|

7 members (+8Rich, Bishmog, DCH, Anonymouse, Tony Quinn, BLUE+4, Hamwich),

413

guests, and

42

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|

|

|

|

|

|

|

|

|

SORN

by OldSkrote - 31/07/25 02:07 PM

|

New

by Rex_tulips - 30/07/25 07:59 PM

|

|

|

Forums34

Topics48,375

Posts813,506

Members9,215

| |

Most Online1,046

Aug 24th, 2023

|

|

|

|

Joined: Nov 2013

Posts: 1,944

Talk Morgan Enthusiast

|

OP

Talk Morgan Enthusiast

Joined: Nov 2013

Posts: 1,944 |

The compensator on my car has started to get noisy or at least I take it to be the compensator. I was occasionally getting a rattle at cold start but it would go away. Today at 2800 miles it was rattling at start, but now at town speeds & light load or overrun its rattling. It quietens on load & not noticed it at higher speed.

My car does not have the grease nipple fitted to the compensator. I've contacted the dealer to see if a grease nipple can be fitted. My car No 0757 was built June 2013 I believe. If greasing is not possible or does not stop the rattle I asked cost to me of an upgraded Centa compensator. Can the dealer fit this?

Tim

|

|

|

|

|

Joined: Oct 2012

Posts: 6,538

Talk Morgan Sage

|

Talk Morgan Sage

Joined: Oct 2012

Posts: 6,538 |

This sounds very like the dreaded Compensator failure....am afraid it will get worse:(((

Only solution is a new Centra drive. The dealer can fit - it goes into the existing bell housing.

Neil

|

|

|

|

|

Joined: Apr 2012

Posts: 1,649

Talk Morgan Enthusiast

|

Talk Morgan Enthusiast

Joined: Apr 2012

Posts: 1,649 |

If it is this you may find that the dealer will forgo the pleasure of fitting as it is a very big job and they will never do it in the target amount of time MMC recommend.

Good luck, it may not be that bad.

2022 Plus Four, 2023 Super Three, Range Rover Vogue SDV8 and Triking T3.

|

|

|

|

|

Joined: Jan 2013

Posts: 400

Learner Plates Off!

|

Learner Plates Off!

Joined: Jan 2013

Posts: 400 |

My dealer did fit a grease nipple and I must say the compensator is transformed. Much less rattles but a new whine, if I may call it that. Maybe the whine was hidden by the old rattles, who knows? Quieter, but not by any means quiet.

It now allows 2200 rpm and above without problems.

It makes a BIG difference.

My car is #674, built i April -13.

M3W, now!!!

|

|

|

|

|

Joined: Nov 2013

Posts: 1,944

Talk Morgan Enthusiast

|

OP

Talk Morgan Enthusiast

Joined: Nov 2013

Posts: 1,944 |

Donald

Did you have the Centra compensator fitted with your upgrades? Do you think this is the answer to the compensator problem?

tim

|

|

|

|

|

Joined: Apr 2012

Posts: 1,649

Talk Morgan Enthusiast

|

Talk Morgan Enthusiast

Joined: Apr 2012

Posts: 1,649 |

Tim,

yes I had the factory do the upgrades. It seemed a little unfair that they wanted the car back there rather than let the dealer do it.

I had the NVH (IMHO pointless and very expensive) the fan (Good if you are in warm climes or traffic) and the Comfort Pack! They noticed after changing the BB that the compensator was goosed. It needed a quieter BB to hear the bag of spanners moving about. The new Centa is not quiet but maybe better as long as you keep the revs on. I cannot say definitively that it is the answer.

2022 Plus Four, 2023 Super Three, Range Rover Vogue SDV8 and Triking T3.

|

|

|

|

|

Joined: Oct 2012

Posts: 2,777 Likes: 61

Talk Morgan Expert

|

Talk Morgan Expert

Joined: Oct 2012

Posts: 2,777 Likes: 61 |

Tim

Don't know of any Centa failures. The Centa does make its own rattles but fewer than the original type and doesn't need the same degree of care when driving to avoid the full on clattering.

Only time and miles will tell if the Centa is as good as it is billed.

|

|

|

|

|

Joined: Nov 2013

Posts: 1,944

Talk Morgan Enthusiast

|

OP

Talk Morgan Enthusiast

Joined: Nov 2013

Posts: 1,944 |

My compensator has been quiet up to now.

By the way John Printie has left Revolutions to look after his wife. Kimberly is picking up the phone & doing liason.

Tim

Last edited by TimG; 15/07/14 08:01 AM.

|

|

|

|

|

Joined: Jan 2013

Posts: 417

Learner Plates Off!

|

Learner Plates Off!

Joined: Jan 2013

Posts: 417 |

get the centra. as red three states is the only long term solution as the other routes are just bandaids to an inferior setup unfortunately.

blake

sfmorgan.tumblr.com

|

|

|

|

|

Joined: Apr 2012

Posts: 1,649

Talk Morgan Enthusiast

|

Talk Morgan Enthusiast

Joined: Apr 2012

Posts: 1,649 |

Centa is no panacea but an improvement and should last.

2022 Plus Four, 2023 Super Three, Range Rover Vogue SDV8 and Triking T3.

|

|

|

|

|

Joined: Jan 2013

Posts: 400

Learner Plates Off!

|

Learner Plates Off!

Joined: Jan 2013

Posts: 400 |

I just want to stress that I am quite happy with what ever the grease nipple has done. Wether it lasts I have no idea, I have only done a 1000 km after the upgrade.

As far as I know it was done under warranty.

M3W, now!!!

|

|

|

|

|

Joined: Jan 2014

Posts: 462

Learner Plates Off!

|

Learner Plates Off!

Joined: Jan 2014

Posts: 462 |

Is there a tread on where and how to install the compensator grease fitting ?

JV Sclafani

Boca Raton, FL

'13 M3W Metallic Orange Pearl

128CI Steered by Empire - Riding on Ohlins

|

|

|

|

|

Joined: May 2012

Posts: 1,790 Likes: 3

Talk Morgan Enthusiast

|

Talk Morgan Enthusiast

Joined: May 2012

Posts: 1,790 Likes: 3 |

My compensator was changed last September for one with a grease nipple in. When it starts to get a bit noisy I pump some high pressure grease in and that sorts it out. It is now that quiet all I can hear is the BB instead.

|

|

|

|

|

Joined: Aug 2012

Posts: 2,356 Likes: 2

Talk Morgan Expert

|

Talk Morgan Expert

Joined: Aug 2012

Posts: 2,356 Likes: 2 |

So do i

After a big ride i put grease And it is quiet.

|

|

|

|

|

Joined: Jul 2013

Posts: 3,660 Likes: 48

Talk Morgan Addict

|

Talk Morgan Addict

Joined: Jul 2013

Posts: 3,660 Likes: 48 |

So where is the grease going?

I thought it was a sealed unit.

Red Leader

|

|

|

|

|

Joined: Aug 2012

Posts: 2,356 Likes: 2

Talk Morgan Expert

|

Talk Morgan Expert

Joined: Aug 2012

Posts: 2,356 Likes: 2 |

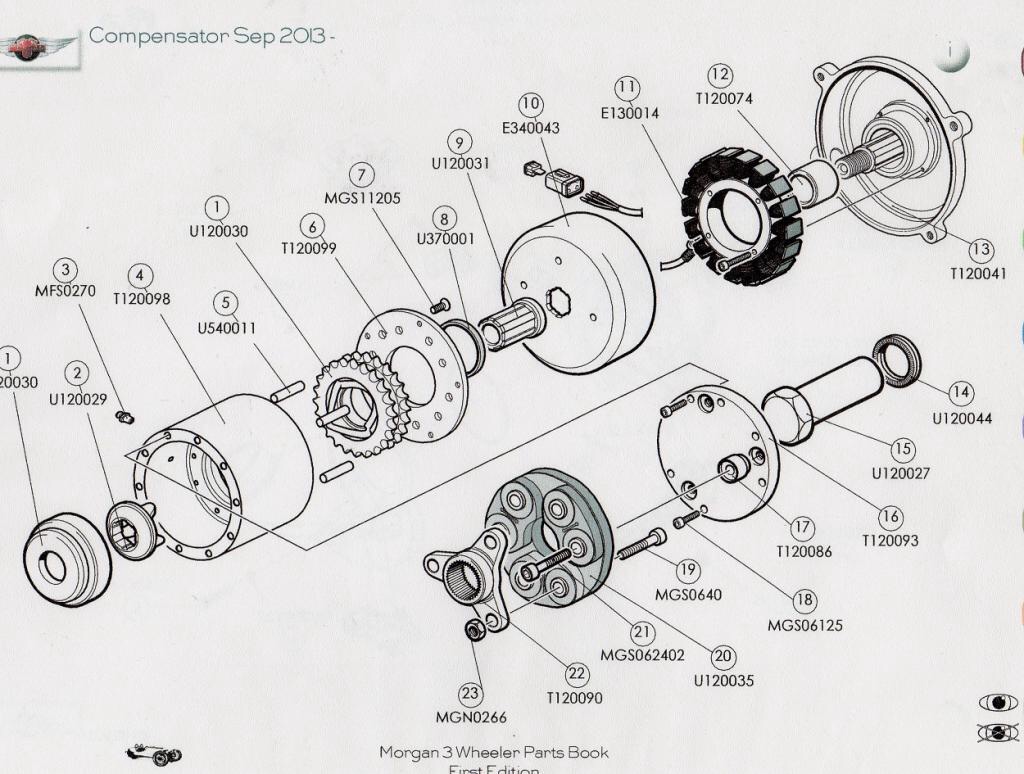

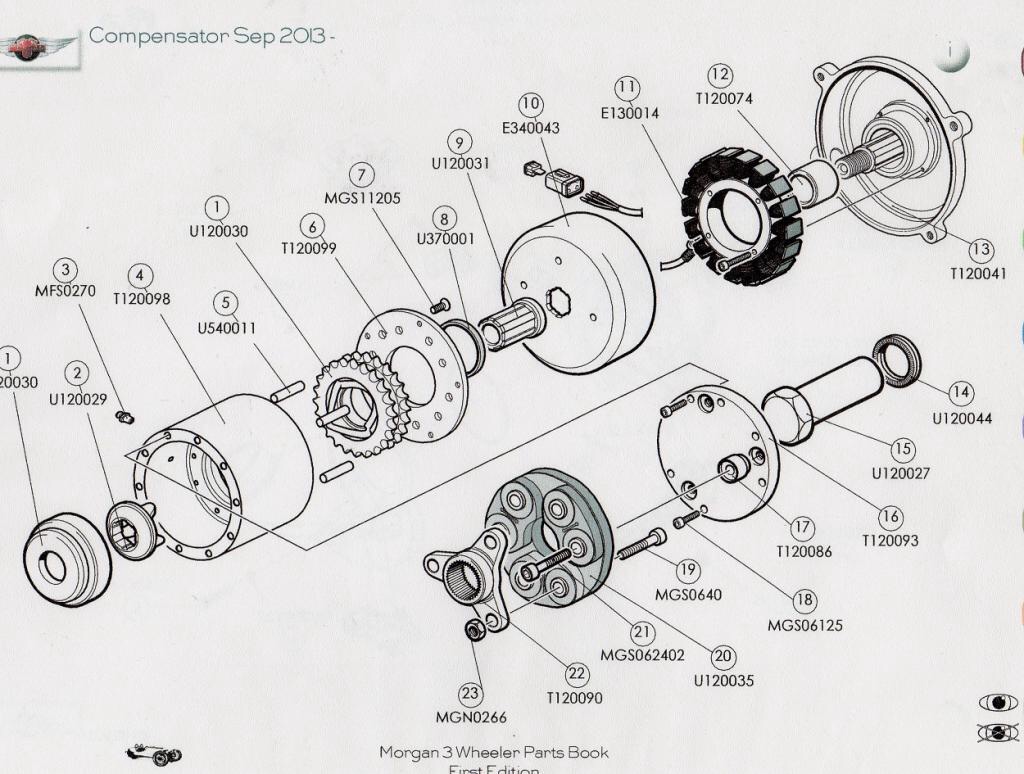

p In the cylinder on the left

Last edited by atalante83; 21/07/14 04:06 PM.

|

|

|

|

|

Joined: Oct 2012

Posts: 6,538

Talk Morgan Sage

|

Talk Morgan Sage

Joined: Oct 2012

Posts: 6,538 |

Wow - what an interesting diagram!!! thanks for posting!!

Neil

|

|

|

|

|

Joined: Aug 2012

Posts: 2,356 Likes: 2

Talk Morgan Expert

|

Talk Morgan Expert

Joined: Aug 2012

Posts: 2,356 Likes: 2 |

|

|

|

|

|

Joined: Aug 2012

Posts: 2,356 Likes: 2

Talk Morgan Expert

|

Talk Morgan Expert

Joined: Aug 2012

Posts: 2,356 Likes: 2 |

Is there a tread on where and how to install the compensator grease fitting ? Number 3

Last edited by atalante83; 21/07/14 05:20 PM.

|

|

|

|

|

Joined: Jan 2014

Posts: 1,075

Has a lot to Say!

|

Has a lot to Say!

Joined: Jan 2014

Posts: 1,075 |

p In the cylinder on the left My question has always been this, why have all the complicated compensator when they have the BMW type driveshaft torsional damper, item 20 that on my quote picture is cropped on the side, but is the lower right part with a bunch of holes in it. I was thinking that they're obviously strong enough for a BMW sedan to use on their drive shaft and one has more than enough to work on a M3W, why not stack three of them keeping each as a separate in series stack? I think that would be a great compensator without any moving parts, so to speak. No grease and self aligning. The motor crank would stabilize the one end of the stack and the flywheel for trans through the adapter plate bearing would hold true the clutch end. I think there would be more than enough strength as well as shock absorbing capabilities to do the jog. Then Centa is still rubber inserts being pressed and this would just be rubber twisting. Any thoughts on this as an option? It would sure be cheaper as these rubber couplings sell on ebay for under $40 each. So three would be $120 and bolting them together shouldn't cost much. The motor plate on the rotor could be tapped to bolt directly to it on one end and the other end already has the rubber ring and adapter that slides over the trans flywheel input shaft. It seems like a no brainer to me, again thoughts?

Dan

|

|

|

|

|

Joined: Feb 2012

Posts: 5,653 Likes: 4

Charter Member

|

Charter Member

Joined: Feb 2012

Posts: 5,653 Likes: 4 |

My guess is that you may not get or maintain sufficient alignment to get a perfectly balanced assembly.

Martin (Deano)

|

|

|

|

|

Joined: Oct 2012

Posts: 2,777 Likes: 61

Talk Morgan Expert

|

Talk Morgan Expert

Joined: Oct 2012

Posts: 2,777 Likes: 61 |

The transient torque loadings are the problem with the S&S engine. It seems that they are truly massive and even Centa were surprised by how difficult it was to smooth things out enough.

|

|

|

|

|

Joined: Feb 2011

Posts: 14,009

Member of the Inner Circle

|

Member of the Inner Circle

Joined: Feb 2011

Posts: 14,009 |

From memory the absolute torque loadings peak at around 1150 lb/ft. Quite scary!

Jays

Former Morgan owner. Gone but hopefully not forgotten!

|

|

|

|

|

Joined: Jun 2013

Posts: 1,461

Has a lot to Say!

|

Has a lot to Say!

Joined: Jun 2013

Posts: 1,461 |

From memory the absolute torque loadings peak at around 1150 lb/ft. Quite scary! 1150?! How can that be?

|

|

|

|

|

Joined: Oct 2012

Posts: 2,777 Likes: 61

Talk Morgan Expert

|

Talk Morgan Expert

Joined: Oct 2012

Posts: 2,777 Likes: 61 |

From memory the absolute torque loadings peak at around 1150 lb/ft. Quite scary! 1150?! How can that be? Extremely short spikes of torque. The normally quoted torque figure can be thought of as an average over a couple of revolutions of the crank. The inertia of the mass of the crank will help smooth things out compared to a lightweight crank but the S&S needs more help than most.

|

|

|

|

|

Joined: Feb 2011

Posts: 14,009

Member of the Inner Circle

|

Member of the Inner Circle

Joined: Feb 2011

Posts: 14,009 |

From memory the absolute torque loadings peak at around 1150 lb/ft. Quite scary! 1150?! How can that be? It can't. He's never been the same since the sausage sandwich thread  Oi.........I like my sausage sandwiches Mike! I was a tad out on the torque......a quote from Andrew English article in the Telegraph. "At the heart of the Three Wheeler is its V-twin engine from S&S of Wisconsin, USA. Known as the X-Wedge and introduced in 2007, this 1,982cc, dry-sump unit has a 56.25-degree angle, a solid, forged 43lb crank for longevity and engine balance at idle and three belt-driven camshafts to allow almost straight pushrods. Retailing at approximately �6,700 in the States, this two-valve, fuel-injected unit punches out 115bhp and 100lb ft of torque with peak revs at 5,200rpm. It�s like a Harley unit but better: S&S has been in the engine business since 1956 and is highly respected. The trouble is, torque kills transmissions. S&S says it produces torque spikes of 1,800lb ft, which makes the gears clash and sing against each other. Reeves and his team, together with S&S, have adapted a Harley-Davidson mechanical cushion drive, which successfully irons out the firing impulses. The engine sits on a rubber-mounted bed plate and the stainless steel exhausts have flexible couplings and mountings. Start her up and you see a lot of movement, but the cabin and major controls are stock still."

Jays

Former Morgan owner. Gone but hopefully not forgotten!

|

|

|

|

|

Joined: Nov 2013

Posts: 1,944

Talk Morgan Enthusiast

|

OP

Talk Morgan Enthusiast

Joined: Nov 2013

Posts: 1,944 |

I'm still waiting for the dealer to get back to me on whether or not a grease nipple can be fited. That's been a week with no answer from Morgan.

Tim

|

|

|

|

|

Joined: Jun 2013

Posts: 1,461

Has a lot to Say!

|

Has a lot to Say!

Joined: Jun 2013

Posts: 1,461 |

"S&S says it produces torque spikes of 1,800lb ft, which makes the gears clash and sing against each other..." Blimey. If that is so, no wonder the word 'humungous' was invented.

|

|

|

|

|

Joined: Jul 2013

Posts: 3,660 Likes: 48

Talk Morgan Addict

|

Talk Morgan Addict

Joined: Jul 2013

Posts: 3,660 Likes: 48 |

I'm still waiting for the dealer to get back to me on whether or not a grease nipple can be fited. That's been a week with no answer from Morgan.

Tim In the words of Monty Python - a week, you were lucky! I'm at 2 months and counting......

Red Leader

|

|

|

|

|

Joined: Oct 2011

Posts: 3,515 Likes: 8

Talk Morgan Addict

|

Talk Morgan Addict

Joined: Oct 2011

Posts: 3,515 Likes: 8 |

Sounds like a question for Mark. Have you tried the help line Mike?

Paul

[At last, I have a car I can polish]

|

|

|

|

|

Joined: Apr 2012

Posts: 1,649

Talk Morgan Enthusiast

|

Talk Morgan Enthusiast

Joined: Apr 2012

Posts: 1,649 |

Mike that is very funny, thanks for making me smile.

2022 Plus Four, 2023 Super Three, Range Rover Vogue SDV8 and Triking T3.

|

|

|

|

|

Joined: Aug 2012

Posts: 2,356 Likes: 2

Talk Morgan Expert

|

Talk Morgan Expert

Joined: Aug 2012

Posts: 2,356 Likes: 2 |

|

|

|

|

|

Joined: Nov 2013

Posts: 1,944

Talk Morgan Enthusiast

|

OP

Talk Morgan Enthusiast

Joined: Nov 2013

Posts: 1,944 |

I heard from the dealer but my questions not fully answered. They will replace compensator under warranty like for like. If I want the Centa there will be a cost to me. Why would they fit a component known to be inadequate & might have to do it again?

My question as to fitting a grease nipple was not answered. I asked if it can be done who pays. Is it worth while if they expect me to pay or just go for centa?

Tim

|

|

|

|

|

Joined: Oct 2011

Posts: 3,515 Likes: 8

Talk Morgan Addict

|

Talk Morgan Addict

Joined: Oct 2011

Posts: 3,515 Likes: 8 |

My car was made just before yours Tim, and registered on 1st June 2013, so I am watching your thread with great interest. So far mine is quiet, but I have no reason to suppose it will remain so.

Did I recall that the cost for the improved Centa unit was �700 fitted? I believe that this is close to cost price, however, I agree with you that the original component is not fit for the purpose, so why should we accept a substandard piece when a better one is available?

I know many people have gone down the route of paying for the latest one, possibly in exasperation at not having a working car, and whilst I would not want to take advantage of Morgan, equally, I would not want them to take advantage of me, or any other customers' goodwill.

I think the point resolves around current consumer law in the UK, something which I know very little about, but are there any 'experts' here who can clarify the situation?

Paul

[At last, I have a car I can polish]

|

|

|

|

|

Joined: Oct 2012

Posts: 6,538

Talk Morgan Sage

|

Talk Morgan Sage

Joined: Oct 2012

Posts: 6,538 |

The Sale of Goods Act is your protection!goods must be "fit for purpose"

Not an expert - but if u google this - the facts are all there!

Neil

|

|

|

|

|

Joined: Aug 2012

Posts: 2,356 Likes: 2

Talk Morgan Expert

|

Talk Morgan Expert

Joined: Aug 2012

Posts: 2,356 Likes: 2 |

When they put first compensator they could do the job ( putting grease nipple And hole for putting it )

On my superdry it is ok

Why not trying this on the waranty if you are not satisfied you could always pay an extra for the centa.

|

|

|

|

|

Joined: Jan 2014

Posts: 1,670

Talk Morgan Enthusiast

|

Talk Morgan Enthusiast

Joined: Jan 2014

Posts: 1,670 |

So when you're a second or third owner?

I guess you simply wait for it to go eh? Then splash out on a Centra - are they so much better?

My car is an April 12 build and yes I'm a little concerned

|

|

|

|

|

Joined: Jan 2012

Posts: 374

Learner Plates Off!

|

Learner Plates Off!

Joined: Jan 2012

Posts: 374 |

I guess you simply wait for it to go eh?

I'm the first owner of mine. Warranty ends jan 15. Dealer's advice; drive it lots so it breaks before the warranty expires. Then you have two choices; either have another of the original compensators fitted for "free" (you "only" pay the transportation to the factory... Which is not exactly cheap!), or you pay more for the new Centra one. If you decide not to wait for it to break and just go for the Centra (maybe you don't want to drive a ticking bomb, knowing it will one day leave you stranded) then you pay the transportation, the parts AND the labour. This will apparently also be the case if it breaks once the warranty is up. My compensator sounds bad already (passengers always remark on it). But I don't think it's near the end of its life yet. The more I think about this, the more annoyed I get!

|

|

|

|

|

Joined: Jul 2013

Posts: 1,338

Has a lot to Say!

|

Has a lot to Say!

Joined: Jul 2013

Posts: 1,338 |

|

|

|

|

|

Joined: Aug 2012

Posts: 2,356 Likes: 2

Talk Morgan Expert

|

Talk Morgan Expert

Joined: Aug 2012

Posts: 2,356 Likes: 2 |

|

|

|

|

|

Joined: Jun 2013

Posts: 1,461

Has a lot to Say!

|

Has a lot to Say!

Joined: Jun 2013

Posts: 1,461 |

It's Centa and VSpec's information is accurate, apart from his misspelling of Centa. I think it costs a bit more than that, Raphael... more like 800 euros. but perhaps my memory has been boiled by a hot afternoon in a three-wheeled sauna tub between Toulouse and Bargemon.

|

|

|

|

|

Joined: Aug 2012

Posts: 2,356 Likes: 2

Talk Morgan Expert

|

Talk Morgan Expert

Joined: Aug 2012

Posts: 2,356 Likes: 2 |

My car was made just before yours Tim, and registered on 1st June 2013, so I am watching your thread with great interest. So far mine is quiet, but I have no reason to suppose it will remain so.

Did I recall that the cost for the improved Centa unit was �700 fitted? I believe that this is close to cost price, however, I agree with you that the original component is not fit for the purpose, so why should we accept a substandard piece when a better one is available?

I know many people have gone down the route of paying for the latest one, possibly in exasperation at not having a working car, and whilst I would not want to take advantage of Morgan, equally, I would not want them to take advantage of me, or any other customers' goodwill.

I think the point resolves around current consumer law in the UK, something which I know very little about, but are there any 'experts' here who can clarify the situation?

|

|

|

|

|

Joined: Jun 2013

Posts: 1,461

Has a lot to Say!

|

Has a lot to Say!

Joined: Jun 2013

Posts: 1,461 |

Ah, yes, my brain has indeed boiled. I saw a euro sign when it was a pound sign!

|

|

|

|

|

Joined: Jun 2013

Posts: 1,461

Has a lot to Say!

|

Has a lot to Say!

Joined: Jun 2013

Posts: 1,461 |

As they used to say in the music halls, "Don't ask I..."

|

|

|

|

|

Joined: Apr 2012

Posts: 1,649

Talk Morgan Enthusiast

|

Talk Morgan Enthusiast

Joined: Apr 2012

Posts: 1,649 |

My car was recovered to factory and I collected it, good excuse to get a factory tour.

I believe the Centa is a longer term solution and is maintenance free, allegedly.

2022 Plus Four, 2023 Super Three, Range Rover Vogue SDV8 and Triking T3.

|

|

|

|

|

Joined: Aug 2012

Posts: 2,356 Likes: 2

Talk Morgan Expert

|

Talk Morgan Expert

Joined: Aug 2012

Posts: 2,356 Likes: 2 |

If it works for a long time .......perhaps

|

|

|

|

|

Joined: Apr 2012

Posts: 1,649

Talk Morgan Enthusiast

|

Talk Morgan Enthusiast

Joined: Apr 2012

Posts: 1,649 |

You are right Raphy,

keep lubricating yours and it maybe will work for a long time too. I hope a lot of compensators have longevity. You lavish attention on those three MOGS of yours.

Now get out on the golf course.

2022 Plus Four, 2023 Super Three, Range Rover Vogue SDV8 and Triking T3.

|

|

|

|

|

Joined: Oct 2012

Posts: 6,538

Talk Morgan Sage

|

Talk Morgan Sage

Joined: Oct 2012

Posts: 6,538 |

Vspec - sad to say that the original Comp will just keep getting worse and worse:((((

Neil

|

|

|

|

|

Joined: Aug 2013

Posts: 115

L - Learner Plates On

|

L - Learner Plates On

Joined: Aug 2013

Posts: 115 |

Just so I understand this correctly.........

If the housing for the comp has the large hole underneath then it should have a comp with the grease nipple?

Or do all of the housings have the access hole and only some comps have the zerk fitting?

DOG is my Co-Pilot

|

|

|

|

|

Joined: Mar 2013

Posts: 712 Likes: 8

Talk Morgan Regular

|

Talk Morgan Regular

Joined: Mar 2013

Posts: 712 Likes: 8 |

Just so I understand this correctly.........

If the housing for the comp has the large hole underneath then it should have a comp with the grease nipple?

Or do all of the housings have the access hole and only some comps have the zerk fitting? This is what I was also curious of. And to make a grease nipple, just drill a hole and make thread in it ?

|

|

|

|

|

Joined: Jan 2014

Posts: 1,075

Has a lot to Say!

|

Has a lot to Say!

Joined: Jan 2014

Posts: 1,075 |

Another comparison here to Harley, but it may be very close.

In the old days with Harley, they used a ramp type compensator very similar to what you have on your M3W's. Let's take that a bit further, Harley today uses a compensator with ramps just about like the old style. But the old bikes with their 74" to 88" size motors lasted a VERY long time.

Now that Harleys smallest Big Twin is a 103" and like mine with the 110" motors, the compensators are failing at a lot faster clip and has been a BIG problem with many riders.

So the design is okay for smaller lower torque motors, but 100" up to 120" where you guys are, is not working for Morgan or Harley.

Sad to say, I'm only repeating what's already been said here, it isn't if they fail, but when they fail.

On Harley's latest version they added a Torrington needle bearing thrust setup and they have also designed a scoop on the inside of the primary cover to collect and drip oil right back onto the bearing and ramps. So far this one is working a bit better than the last three iterations, but time will probably prove it as a failure too.

So something like the Centa with the four rubber logs being compressed back and forth with the torque pulses within the rounded slots in the inner and outer housing of the new compensator, this is probably the way to go for a long term fix.

Someone said that their Centa created a vibration. There is no way on the design to go out of balance unless one of the logs literally disintegrated and fell out. Or maybe the rubber is not forgiving enough and the vibration is actually the torque pulses coming through the driveline.

I do really wish you guy a good solution to the comp problems.

Dan

|

|

|

|

|

Joined: Aug 2013

Posts: 797

Talk Morgan Regular

|

Talk Morgan Regular

Joined: Aug 2013

Posts: 797 |

Dan your spot on with this. The compensator isn't just similar to a Harley! it f from a Harley. I get my 3W back from the factory tomorrow, complete with new chassis.

They said they get it Done within a month and fair ply it's back on time.

Report tomorrow

Last edited by Matty; 24/07/14 09:52 PM.

|

|

|

|

|

Joined: Apr 2012

Posts: 1,649

Talk Morgan Enthusiast

|

Talk Morgan Enthusiast

Joined: Apr 2012

Posts: 1,649 |

Matty,

have a safe and trouble free journey, hope you will be grinning from ear to ear.

D

2022 Plus Four, 2023 Super Three, Range Rover Vogue SDV8 and Triking T3.

|

|

|

|

|

Joined: Feb 2014

Posts: 167

L - Learner Plates On

|

L - Learner Plates On

Joined: Feb 2014

Posts: 167 |

Hello Matty,

Pleased to hear you will have your car back today. Enjoy the rest of the summer. You deserve it!

|

|

|

|

|

Joined: Oct 2011

Posts: 3,515 Likes: 8

Talk Morgan Addict

|

Talk Morgan Addict

Joined: Oct 2011

Posts: 3,515 Likes: 8 |

Best of luck with it Matty, maybe we'll have another meet at Compton Abbas in Septmber, which you will be able to enjoy properly?

Paul

[At last, I have a car I can polish]

|

|

|

|

|

Joined: Nov 2013

Posts: 1,944

Talk Morgan Enthusiast

|

OP

Talk Morgan Enthusiast

Joined: Nov 2013

Posts: 1,944 |

More info from my dealer Revolutions in Perth. I've booked in for them to fit the grease nipple to the compensator at no cost to me. They have done several & it takes around 30 minutes.

Revolutions can & will fit the old style compensator if it fails with like for like plus grease nipple. They can do it in 8 to 9 hours & have done several as a warranty job.

If I wanted a centa compensator there would be a charge, it takes a lot longer to change to centa & there would be a cost to me but I dont know how much or if they can do it.

The factory closes this evening till Monday 4th August so I guess if you are waiting for info you will have to wait a bit longer.

Raphael, what grease are you using & how often do you need to grease it?

Tim.

|

|

|

|

|

Joined: Jul 2013

Posts: 1,338

Has a lot to Say!

|

Has a lot to Say!

Joined: Jul 2013

Posts: 1,338 |

My m3w is a october/2013 build,with no grease nipple...should i leave it as is until it breaks & install the centa...can grease be put from the top just behind the engine?there is a open area

|

|

|

|

|

Joined: Jul 2011

Posts: 1,948

Talk Morgan Enthusiast

|

Talk Morgan Enthusiast

Joined: Jul 2011

Posts: 1,948 |

My m3w is a october/2013 build,with no grease nipple...should i leave it as is until it breaks & install the centa...can grease be put from the top just behind the engine?there is a open area There is a dilemma here. Should you extend the working life of a compromised part through diligent maintenance and have it fail just outside the warranty period? Or leave it alone and have the Centa unit fitted if/when it fails...

Stuart

"There's no skill substitute like cubic inches."

|

|

|

|

|

Joined: Feb 2012

Posts: 5,653 Likes: 4

Charter Member

|

Charter Member

Joined: Feb 2012

Posts: 5,653 Likes: 4 |

My m3w is a october/2013 build,with no grease nipple...should i leave it as is until it breaks & install the centa...can grease be put from the top just behind the engine?there is a open area There is a dilemma here. Should you extend the working life of a compromised part through diligent maintenance and have it fail just outside the warranty period? Or leave it alone and have the Centa unit fitted if/when it fails... Personally I would want it to fail under warranty and have the upgrade installed.

Martin (Deano)

|

|

|

|

|

Joined: Aug 2013

Posts: 242

L - Learner Plates On

|

L - Learner Plates On

Joined: Aug 2013

Posts: 242 |

I don't think you will get the Centa though. MMC will try and fit the original setup and charge you to upgrade.

|

|

|

|

|

Joined: Oct 2011

Posts: 3,515 Likes: 8

Talk Morgan Addict

|

Talk Morgan Addict

Joined: Oct 2011

Posts: 3,515 Likes: 8 |

That is their stated policy, but do we know if it has ever been challenged legaly, indeed, is there, in fact, a legal challenge when a known faulty design of part is replaced with another of the same type, when a better part is subsequently in use?

Paul

[At last, I have a car I can polish]

|

|

|

|

|

Joined: Feb 2012

Posts: 5,653 Likes: 4

Charter Member

|

Charter Member

Joined: Feb 2012

Posts: 5,653 Likes: 4 |

That is their stated policy, but do we know if it has ever been challenged legaly, indeed, is there, in fact, a legal challenge when a known faulty design of part is replaced with another of the same type, when a better part is subsequently in use? Easily justified by the inconvenience of the failure.

Martin (Deano)

|

|

|

|

|

Joined: Jul 2013

Posts: 1,338

Has a lot to Say!

|

Has a lot to Say!

Joined: Jul 2013

Posts: 1,338 |

I cant do any warrenty work.as i am all alone in kuwait & there is no dealer here..does anyone know on how to install the centa..is it a direct bolt on part?my m3w has maybe 2000kms..i wont be able to drive it till october..its too hot..but i just ordered the urban cooling kit & will get it polished & ready

|

|

|

|

|

Joined: Aug 2013

Posts: 797

Talk Morgan Regular

|

Talk Morgan Regular

Joined: Aug 2013

Posts: 797 |

Thanks guys

Got the beast back today.

Feels good, cooling fan upgrade well worth it. feels tighter and they must have done an upgrade engine mapping wise. feels smoother. NVH kits comes with new chassis and all appears very civilised. Brand new Spax shocks also fitted at no cost. Centa drive which was already fitted to my 3w is now smoother with no vibration at the moment. New bevel box was fitted also and is reasonably quiet. still has some backlash. Joy cut short by rain storm but can't wait for the weekend.

Morgan have been more than as good as there word with me. I just hope this sorts out the 3W for good. I want this to work for all of us and Morgan. Fingers crossed. Hope to lots of you guys now I'm back on the road.

|

|

|

|

|

Joined: Oct 2012

Posts: 6,538

Talk Morgan Sage

|

Talk Morgan Sage

Joined: Oct 2012

Posts: 6,538 |

Matty - what do you mean x "backlash"?

Neil

|

|

|

|

|

Joined: Oct 2012

Posts: 6,538

Talk Morgan Sage

|

Talk Morgan Sage

Joined: Oct 2012

Posts: 6,538 |

I cant do any warrenty work.as i am all alone in kuwait & there is no dealer here..does anyone know on how to install the centa..is it a direct bolt on part?my m3w has maybe 2000kms..i wont be able to drive it till october..its too hot..but i just ordered the urban cooling kit & will get it polished & ready Q8 the Centa drive fits inside the original Bell housing - its the internals which are so v different. Its an engine out job tho!

Last edited by m3boy; 25/07/14 04:44 PM.

Neil

|

|

|

|

|

Joined: Oct 2011

Posts: 3,515 Likes: 8

Talk Morgan Addict

|

Talk Morgan Addict

Joined: Oct 2011

Posts: 3,515 Likes: 8 |

"the Centa drive fits inside the original Bell housing"

I assume you don't mean actual bellhousing, but the elongated ali. casing that is bolted between the bellhousing and the back of the engine?

I'm not being pedantic, just making sure we are all able to identify the correct part. I was unaware that the Centa drive unit fitted inside the existing case, which is why there is more work to do, hence the extra charge.

Paul

[At last, I have a car I can polish]

|

|

|

|

|

Joined: Oct 2012

Posts: 6,538

Talk Morgan Sage

|

Talk Morgan Sage

Joined: Oct 2012

Posts: 6,538 |

Yep it fits inside the original Compensator housing. look to me like nothing changes on the outside of the housing. Hope this helps.

Neil

|

|

|

|

|

Joined: Aug 2013

Posts: 797

Talk Morgan Regular

|

Talk Morgan Regular

Joined: Aug 2013

Posts: 797 |

Well on overrun, change down to second or first for a slow corner and when I release the clutch I've always had an intermittent clunk. feels like slack in the bevel box but I suppose if that was the case you would feel it in any gear clutch used or not.

Trouble is any issues anywhere in the drivetrain tend to transmit anywhere. does that make sense?

|

|

|

|

|

Joined: Jan 2014

Posts: 1,075

Has a lot to Say!

|

Has a lot to Say!

Joined: Jan 2014

Posts: 1,075 |

Okay guys, here's another Dan post...

Way back when I bought a new 2004 Nissan Titan 4x4 pickup truck, it was a new product line for '04. You know what they say, don't buy a first year vehicle, but this truck was kick butt and had an awesome Rockford Fossgate 13 speaker with sub system. Other than the lack luster economy, about 12 mpg, the truck was a very nice and dependable truck, and did I mention the kick butt factory sound system???

Well very early on Nissan found out they had undersized the front rotors and calipers. The rotor warped badly and the brake would vibrate back through the pedal, they called this brake judder. Anyway they came out with all sorts of letters etc about the problem, but the fix was not handled very well.

If you had brake problems, and everyone eventually did, it was required that you go through three (3), yes three rotor turnings and new pads BEFORE they would upgrade you to new larger rotors and calipers.

So you had to go in three times for a "fix" and then wait for the final good parts to be installed. Luckily the final fix did a good job and we had no problems afterwards.

Back in '08 thru about '12 with Harley and their compensator issues, if you had a problem you got the same comp put back in. When they came out with their new SE (Screamin' Eagle) performance comp, you still got the old one under warranty. This was even after they started to put the SE comps on their CVO production bikes. Eventually if you yelled load enough to the factory they would do a special allowance and do the upgrade for you. I've read of many guys having to PAY to have the SE comp put in under warranty to replace an old style comp.

Lucky or not, I've not had any comp issues and my bike is now out of warranty. So at some point I'm figuring I'll have to cough up the money to do a new SE comp.

For right now, this seems very similar to MMC and their policy of replacing with the same undersized crap that won't last.

Dan

|

|

|

|

|

Joined: May 2012

Posts: 1,790 Likes: 3

Talk Morgan Enthusiast

|

Talk Morgan Enthusiast

Joined: May 2012

Posts: 1,790 Likes: 3 |

Hi Tim

I add grease when it starts to get noisy, which can be more than 2000 miles between top ups.

The grease I use is a high pressure blue grease from JCB.

Not expensive and locally available.

Whack a third of a cartridge in and you will have no bother. Mine is as quiet as a mouse with no snatching and smooth on/off power take up.

|

|

|

|

|

Joined: Nov 2013

Posts: 756 Likes: 9

Talk Morgan Regular

|

Talk Morgan Regular

Joined: Nov 2013

Posts: 756 Likes: 9 |

Centa The system attaches to the end of the crankshaft instead of the old HD system, replace the motor shaft as flying because it is longer.

|

|

|

|

|

Joined: Jul 2013

Posts: 1,338

Has a lot to Say!

|

Has a lot to Say!

Joined: Jul 2013

Posts: 1,338 |

One question,i have the old compensator,can grease be inserted through the top, under the steering rack,or its a NO NO?

|

|

|

|

|

Joined: Oct 2012

Posts: 6,538

Talk Morgan Sage

|

Talk Morgan Sage

Joined: Oct 2012

Posts: 6,538 |

Well on overrun, change down to second or first for a slow corner and when I release the clutch I've always had an intermittent clunk. feels like slack in the bevel box but I suppose if that was the case you would feel it in any gear clutch used or not.

Trouble is any issues anywhere in the drivetrain tend to transmit anywhere. does that make sense? thanks Matty - good to know that I am not alone!!

Last edited by m3boy; 25/07/14 09:07 PM.

Neil

|

|

|

|

|

Joined: Oct 2012

Posts: 6,538

Talk Morgan Sage

|

Talk Morgan Sage

Joined: Oct 2012

Posts: 6,538 |

But what is the "slack" - I worry that its metal on metal - and that something is going to fail/go bang!

Neil

|

|

|

|

|

Joined: Aug 2013

Posts: 797

Talk Morgan Regular

|

Talk Morgan Regular

Joined: Aug 2013

Posts: 797 |

Well I've been thinking and testing it a bit more. it definitely doesn't happen if you keep the revs up. With motorbikes you would feel it as snatch in the primary chain. On ours beasts I reckon the bevel drive is the likely candidate. All gear trains have backlash to some degree or another or they lock solid. just rock any geared system and you'll feel it. I'm guessing the drivetrain components are running faster than the engine as they may do post overrun when you dip,the clutch and let the engine revs drop, those same components will be taking up the full slack(or backlash) in the various gear trains in this condition. Release the clutch on a slow engine and your removing that load momentarily causing the gear trains to reverse lash if that makes any sense. I reckon there may be more backlash coming off load on most gear trains and that why we feel it more on slow overrun than on acceleration. I think I may be overthinking this!!!!

|

|

|

|

|

Joined: Nov 2013

Posts: 1,944

Talk Morgan Enthusiast

|

OP

Talk Morgan Enthusiast

Joined: Nov 2013

Posts: 1,944 |

Q8 my dealer told me its not a straight swap for the centa more work is involved so the job takes longer than the 8 or 9 hours to swap out old style compensator. Perhaps MMC can give you some guidance on how to do it.

DoO thanks for the greasing info. Do you have a part no for the JCB grease?

Tim.

|

|

|

|

|

Joined: Jul 2013

Posts: 1,338

Has a lot to Say!

|

Has a lot to Say!

Joined: Jul 2013

Posts: 1,338 |

Thanks Tim..i hope this winter i can enjoy it in kuwait hassel free(october thru april)it has 2000km's only since last season..any mantince tips to check/do before using it ?

|

|

|

|

|

Joined: Jan 2012

Posts: 14,976 Likes: 1

Member of the Inner Circle

|

Member of the Inner Circle

Joined: Jan 2012

Posts: 14,976 Likes: 1 |

Isn't JCB grease just "regular" high performance lithium complex grease (the blue stuff). Mine is from Castrol and I *think* it is the same stuff.

Richard

1976 4/4 4 Seater

|

|

|

|

|

Joined: May 2012

Posts: 1,790 Likes: 3

Talk Morgan Enthusiast

|

Talk Morgan Enthusiast

Joined: May 2012

Posts: 1,790 Likes: 3 |

I spoke to a dealer today to book my car in for the annual service and we got to chatting about the Centa unit.

Apparently it needs a completely different fly wheel, which is lighter and therefore improves throttle response and also has a centre actuated clutch release bearing and not the fork type used on the old style compensators.

This is why it seems to take a long time to fit and costs so much.

Grease part number is: 4003/2017

|

|

|

|

|

Joined: Aug 2013

Posts: 797

Talk Morgan Regular

|

Talk Morgan Regular

Joined: Aug 2013

Posts: 797 |

Could that explain the clunk when releasing the clutch on overrun?

|

|

|

|

|

Joined: Nov 2013

Posts: 1,944

Talk Morgan Enthusiast

|

OP

Talk Morgan Enthusiast

Joined: Nov 2013

Posts: 1,944 |

Had the compensator grease nipple fitted on Monday & drove the 90 miles home,all fine. Started car yesterday & its rattling again. Drove 15 miles & parked. On restart did not notice any rattle & there may have been a bit on arriving home. Started it this morning & rattle seems absent.

Where to from here? Buy some blue grease & a gun or just leave it alone till failure then get a Centa fitted. Do they just get louder & louder or fail catastrophically?

Tim

|

|

|

|

|

Joined: Oct 2012

Posts: 6,538

Talk Morgan Sage

|

Talk Morgan Sage

Joined: Oct 2012

Posts: 6,538 |

Tim - sadly the Compensator will get worse and worse - not sure if they "fail" but the noise will increase to unacceptable levels:((

Neil

|

|

|

|

|

Joined: Apr 2012

Posts: 1,649

Talk Morgan Enthusiast

|

Talk Morgan Enthusiast

Joined: Apr 2012

Posts: 1,649 |

As mine died it was hard to hear as the bevel box was going at the same time! It did not fail catastrophically just slowly gave up.

2022 Plus Four, 2023 Super Three, Range Rover Vogue SDV8 and Triking T3.

|

|

|

|

|

Joined: Apr 2013

Posts: 215

L - Learner Plates On

|

L - Learner Plates On

Joined: Apr 2013

Posts: 215 |

Mine left me in 50 miles and took the alternator with him :-)

|

|

|

|

|

Joined: Jul 2013

Posts: 1,338

Has a lot to Say!

|

Has a lot to Say!

Joined: Jul 2013

Posts: 1,338 |

My m3w arrived brand new in nov 2013 .now its has 2000 km's,i hope i can use it this october thru april(cool season)without any issues...as then im thinking of shipping it back to the factory this coming summer for all the new upgrades..my service here has been only engine oil & bb oil..

|

|

|

|

|

Joined: Nov 2013

Posts: 1,944

Talk Morgan Enthusiast

|

OP

Talk Morgan Enthusiast

Joined: Nov 2013

Posts: 1,944 |

Best of luck Q8. Hope you have no trouble.

Tim

|

|

|

|

|

Joined: Nov 2013

Posts: 1,944

Talk Morgan Enthusiast

|

OP

Talk Morgan Enthusiast

Joined: Nov 2013

Posts: 1,944 |

Nadvys

How did it take out the alternator, where is this located?

Tim

|

|

|

|

|

Joined: Oct 2012

Posts: 6,538

Talk Morgan Sage

|

Talk Morgan Sage

Joined: Oct 2012

Posts: 6,538 |

Its an engine out job:(((

Neil

|

|

|

|

|

Joined: Oct 2013

Posts: 38

Just Getting Started

|

Just Getting Started

Joined: Oct 2013

Posts: 38 |

My compensator failed in a dramatic fashion. Tow truck and back to the factory for a re-build. Now it's on it's way out again after being packed with grease so back to the factory after 1500 miles. As it's now out of warranty I have been informed I'll need to pay since I asked for the upgrade and not like for like replacement.

Karl

Wine For My Men...We Ride At Dawn

|

|

|

|

|

Joined: Oct 2013

Posts: 6,723 Likes: 2

Talk Morgan Sage

|

Talk Morgan Sage

Joined: Oct 2013

Posts: 6,723 Likes: 2 |

The like-for-like replacement is covered for legally under consumer protection. The 'upgrade' to the latest one is not & will be viewed as such under due process.

Whether you view the original as 'fit for purpose' will be a court room argument requiring much evidence.

Any legal expert will tell you it's far better to enter court on the basis of how much it will cost you, not a principle.

It's up to you Karl, but I'd be attempting negotiation first..

Steve

|

|

|

|

|

Joined: Nov 2013

Posts: 1,944

Talk Morgan Enthusiast

|

OP

Talk Morgan Enthusiast

Joined: Nov 2013

Posts: 1,944 |

Karl even though your car is out of warranty the most you should be asked to pay is the difference in cost between fitting original again & fitting new Centa compensator not the whole cost.

Tim

|

|

|

|

|

Joined: Oct 2012

Posts: 6,538

Talk Morgan Sage

|

Talk Morgan Sage

Joined: Oct 2012

Posts: 6,538 |

Agreed ...its the �� difference IMO - not the full amount.

The original Comp is not fit for purpose ...so lots of negotiating power there.

I would speak to the factory first ...they are reasonable in my experience.

Neil

|

|

|

|

|

Joined: Mar 2014

Posts: 520

Talk Morgan Regular

|

Talk Morgan Regular

Joined: Mar 2014

Posts: 520 |

i had a broken compensator. i paid for the upgrade and they paid for the labour (which they would have done for a like-for-like) i thought that was a perfectly reasonable result for a small manufacturing firm.

someone has to pay for all the work of continuous improvement of the vehicle.

Last edited by charlestkirby; 18/08/14 02:14 PM.

|

|

|

|

|

Joined: Oct 2011

Posts: 3,515 Likes: 8

Talk Morgan Addict

|

Talk Morgan Addict

Joined: Oct 2011

Posts: 3,515 Likes: 8 |

That is quite true Charles, but the question really, is whether the orignal item was a faulty design in the first place, and therefore "not fit for purpose and of merchantable quality". which is what we paid for.

Paul

[At last, I have a car I can polish]

|

|

|

|

|

Joined: Oct 2013

Posts: 38

Just Getting Started

|

Just Getting Started

Joined: Oct 2013

Posts: 38 |

Well I'm quite willing to pay the difference for the "upgrade". As I certainly don't want like for like as it has become bothersome wondering if I'll make it to the bottom of the road with-out another failure happening.

I have also requested the rectifier be mounted in the 3rd new place now. Also the cooling-fan.

Karl

Wine For My Men...We Ride At Dawn

|

|

|

|

|

Joined: Oct 2013

Posts: 38

Just Getting Started

|

Just Getting Started

Joined: Oct 2013

Posts: 38 |

Oh forgot to mention. Tried contacting the factory with-out success.

I know they have lost 2 sales of the M3W because 2 blokes I work with were really stoked about buying them.

Told them wait until at least number 1500 rolls off out the door, not like me with number 6

Karl

Wine For My Men...We Ride At Dawn

|

|

|

|

|

Joined: Oct 2011

Posts: 3,515 Likes: 8

Talk Morgan Addict

|

Talk Morgan Addict

Joined: Oct 2011

Posts: 3,515 Likes: 8 |

Ha, Ha, Ha, Ha, I really like your humour Mike.

Paul

[At last, I have a car I can polish]

|

|

|

|

|

Joined: Oct 2013

Posts: 38

Just Getting Started

|

Just Getting Started

Joined: Oct 2013

Posts: 38 |

a problem of their own making .... you could be considered one wheel short of a road going vehicle  Oh most definitely. I'm on Compensator #2 which is on it's way out as it's sounds exactly the same as Compensator#1 did before it's dramatic failure. This is less than 1500 miles after it was rebuilt by MMC BTW - Compensator#2 was packed full of grease but no grease zerk after the factory rebuild. My local Morgan Dealer drilled and tapped one in and it made not a blind bit of difference after 15 miles. I understand everyone's point of view but as I am out of warranty, don't want like for like and am thoroughly fed up as I just want to drive my Biscuit Tin without it sounding like a demented banshee throttling canaries I will stump up the readies. I think this is because the Maserati has also decided to play silly buggers too. The only reliable vehicle I have is a '92 beaten up old FX-4 London Taxi that's been to the moon and back that I bought for 600 pounds. All in all my advice to anyone with the greased up Compensator is to get the Centa Drive. These are like the Love Joy couplings we use at work. That's my 2 pence worth

Karl

Wine For My Men...We Ride At Dawn

|

|

|

|

|

Joined: Jan 2014

Posts: 16

New to Talk Morgan

|

New to Talk Morgan

Joined: Jan 2014

Posts: 16 |

I spoke to a dealer today to book my car in for the annual service and we got to chatting about the Centa unit.

Apparently it needs a completely different fly wheel, which is lighter and therefore improves throttle response and also has a centre actuated clutch release bearing and not the fork type used on the old style compensators.

This is why it seems to take a long time to fit and costs so much.

Grease part number is: 4003/2017 Tanks for that DAB !

I don't just drive from A to B. I enjoy feeling the cars reaction, becoming part of it-Enzo Ferrari

|

|

|

|

|

Joined: Aug 2012

Posts: 2,356 Likes: 2

Talk Morgan Expert

|

Talk Morgan Expert

Joined: Aug 2012

Posts: 2,356 Likes: 2 |

Mine is compensator 2 with grease

More than 10000 miles And cross fingers " no noise"

|

|

|

|

|

Joined: Jan 2014

Posts: 1,075

Has a lot to Say!

|

Has a lot to Say!

Joined: Jan 2014

Posts: 1,075 |

I spoke to a dealer today to book my car in for the annual service and we got to chatting about the Centa unit.

Apparently it needs a completely different fly wheel, which is lighter and therefore improves throttle response and also has a centre actuated clutch release bearing and not the fork type used on the old style compensators.

This is why it seems to take a long time to fit and costs so much.

Grease part number is: 4003/2017 Tanks for that DAB ! The clutch throw out mechanics have no bearing on what compensator one would have. The throw out bearing and fork is located on the downstream side of the clutch and flywheel. Although most modern cars with hydraulic clutches now use a small slave cylinder mounted around the transmission input shaft support rather than the old style fork with an external slave cylinder. I would see no reason to upgrade the mechanics of the throw out bearing because of the comp upgrade. The fork style has worked well and there is no load on it more or less regardless of the motor etc. For grunting around at lower rpms, which the S&S is very good at doing, a heavier flywheel tends to increase the drivability for cruising, but the light flywheel does come into play when looking at performance. When looking at the v-twin motors, most of the crank assemblies are 30 plus pounds. I would guess this to be lighter than the Miata 1.6L or 1.8L motor usually used in front of the 5 speed you use. Now the S&S I believe uses a forged one piece crank and uses automotive type connecting rods versus the Harley three piece crank with the twin straddle type rods on the same crank pin centerline. The S&S may be lighter than the Harley version, but both still only had the alternator rotor as an external flywheel, so they were overall a lot lighter in rotating mass than the way the M3W is setup. But still I would believe that the extra flywheel weight would be a plus for driving and not a negative. I'm going to speculate a bit here, but if you had a lighter flywheel in a M3W, I would believe that more of the crank pulses would be transmitted through the trans and into the driveshaft and BB. The heavier flywheel, in my mind, would work to dampen the pulses and keep them in front of the flywheel and in the compensator; thus allowing less ratcheting of the transmission innards. Maybe with a 6 speed and lower gears a lighter flywheel would be beneficial, like in hill climbs etc. Just don't see the M3W ever having a crotch rocket type performance. Although Harley has done wonders with the V-Rod in their NHRA drag racing as they usually trounce the Suzuki high revving competition. The Centa works similarly to the Harley style comp as it stores and releases energy pulses from the motor in a somewhat smoothed out manner. The Harley comp has the Bellville springs with the ramps and the Centa uses inner pockets on the shaft and matching pockets in the housing with four rubber logs forced inside each of the pockets. The squishing of the rubber logs back and forth does the same as the ramps pushing back and forth against the spring pack. But theoretically there are no wear parts on the Centa or metal to metal, unless of course the four rubber logs chomp up and disintegrate. I've not seen any "assembled" pictures of the Centa comp, but I can imagine the shaft being splined and bolted to the crank and the end of the shaft just terminates as "X" inches. The housing I see bolting up and being perfectly centered on the motor side of the flywheel; hence the possible need for a new flywheel with the Centa. I then see the four rubber logs being held in the four shaft pockets near the motor end and the trans and motor are then slid together feeding the four logs on the shaft sliding into the Centa housing. Once they are about in, the rubber log retainer would be removed and the motor and trans would then be mated up solid. The shaft would be perfectly centered within the perfectly center housing with the four rubber logs as the only thing connecting the motor with the trans flywheel. It sounds like a great design and should be very trouble free. I'm sure that from what I read on the Centa website that they have decades of experience and providing the "right" durometer of rubber would be no issue for them. Sorry guys, I'm just rambling here as if I were talking to someone and he's not answering me right back... I just don't see the M3W as a high performance vehicle. I would think that a Polaris Slingshot with a "like" size motor would blow the doors off the M3W, but I could be wrong; as I am most of the time...

Dan

|

|

|

|

|

Joined: Dec 2013

Posts: 83

Just Getting Started

|

Just Getting Started

Joined: Dec 2013

Posts: 83 |

Dan,

How goes it?

While gone to Denver, I was notified my Centa bits have shipped...after a 5 month wait...which was long enough that my Bevel Box is on it's way out.

At any rate, I may be able to further elaborate on the Centa soon.

Even with warranty, it's all on my dime as expected.

Z

Last edited by Zackybilly1; 25/08/14 02:11 AM.

|

|

|

|

|

Joined: Jan 2014

Posts: 1,075

Has a lot to Say!

|

Has a lot to Say!

Joined: Jan 2014

Posts: 1,075 |

Z, how's the Iron Butt?

Everything's fine up in the St Louis area. Just a little warm with a heat index of about 110 degress the past few days. Rode the old '76 FLH yesterday and worked up a good sweat while riding.

I hope your Morgan holds together until you get your chang parts.

I still can't imagine that doing the Centa change will take all the time all the dealers are quoting. I think with your background we should see some hours cut from what they claim.

Hope you had a great ride.

Later dude.

Dan

|

|

|

|

|

Joined: Dec 2013

Posts: 83

Just Getting Started

|

Just Getting Started

Joined: Dec 2013

Posts: 83 |

Dan,

I have a feeling the Centa swap is going to drag out going in for the first time...probably will go smoother and gain speed after I've been in and out of it the second or third time. I'm not going to rush the first event as I want to take my time and check hose and harness routing, inspect chassis, mounting tabs, etc. as I've already corrected what was visible and only wonder what I'm not seeing. Without a service manual, I'm sure there will be some Easter Egg hunting. Guess I could generate my own service manual since there doesn't seem to be any other source. While at it, I want to evaluate the charging system as I plan on drawing on it (heated riding gear for winter)...one step closer to being bullet-proof and I want to approach it as if I'm eventually going to have what I bargained for. Sometimes, I can close my eyes and see a Morgan that can take more than I can give it...but for now, it's just an illusive vision.

The Iron Butt event was good. They call it their "international" meet. It was more of a seminar on different aspects of the "big rally" (11,000+ miles in 11 days....routing, bonus points, sleep management, hydration, farkling, etc.)along with some fun. There were riders from all over the country and Canada. Many flew in from over-seas. No matter where in the country you go for the IB events, you see a lot of the same faces. The Iron Butt community is prolific as it pertains to covering ground. As weird as it may sound, the riding style is addictive. When I was younger, it was hotrod motorcycles....I switched gears in to doing long distances instead of warp speeds. That and it helps me utilize my few days off from work more effectively as now I'm not burning up my valuable time off just getting somewhere and back. I went to Denver via Albuquerque, NM, up the Million Dollar Highway (Durango, Silverton, Ouray, Montrose...to Grand Junction then headed east back into Denver). On the way home, I needed to stop in Arkansas to setup a party/ride to eat event. I came through Wichita and spent the night just north of Joplin...next day I was seeing 103*F coming through Missouri. When I get the detail put together on the RTE, I'll forward them to you...it will be just south of Harrison, AR on Scenic Byway 7...an easy ride for you.

I like to travel (keep my foot in the road) and had visions of doing something similar with the M3W but that hasn't gone so well so far. I can't just blindly ride off into the sunset pretending everything is going to be fine. I suspect the SlingShot will do it with ease but it sure as hell won't be as cool as doing it in the M3W. I'm going to take out my Morgan anger and frustration on the Slingshot just as soon as I can get my grimey hands on it. I, also, suspect that riding in the SlingShot will be like riding in a Jeep as compared to the low seating position of the M3W which I like.

With my Morgan like it is now. I don't pick where I'm going in it...I just try to stay on roads that are smooth enough not to beat the chassis to pieces, I stay away from traffic and any stop & go stuff, I try to stay on fast enough roads where I can keep the throttle pinned, drive train loaded and rpms up. That limits where I can go in it but its good enough to keep me interested in it. Above 45 mph, it does okay...it's the lower speed stuff (that you can't avoid forever) where it's weaknesses rear their ugly heads. Mine feels more sanitary at 75 mph than it does at 35 mph. In a nutshell, it has a chassis & suspension that is happier at lower speeds and a drive system that is happier at higher speeds...one doesn't compliment the other. Our road quality is not that great in this part of the country so keeping the slack out of the system isn't always a good option.

After this evenings ride, the bevel box general temp was about 160*F...the front pulley for the belt was around 120*F, the temp in the bearing area at the back of the input shaft was around 170*F and the bearing area of the box at the output shaft was around 175*F (hottest measured temp). It has fresh RedLine HeavyDuty Shockproof gear lube in it for now but I'll be swapping back to RedLine 75w140 after one more cycle with the Shockproof. I drive the M3W in a manner to try to stretch it's life out and try to stay out of the back-lash of the BB. It's not dead yet but suspect it's got one foot in the grave. I still haven't heard back from the dealer on a replacement box which I will order as soon as I get feedback. I don't have any reason to believe the new BB will be any quicker delivery than what I saw on the Centa. Order early and order often, I suppose. I prefer to have parts on the shelf before the existing ones give up the ghost.

I guess if I only had one toy and it was a M3W, it would be a gearhead's dream. I'm still bum-fuzzled over what I got for the money I spent. I spend a lot of money on other toys and don't have any remorse as they work as advertised. The M3W was the same price as a base model C7 Corvette with 455 hp, traction control, stability control, 7-speed manual transmission, variable fuel mapping, cruise control, air conditioning, a removable roof, G-force meters, gobs of instrumentation...and Chevrolet encourages you to take it to the track. They are on the opposite ends of the "bang for your buck" scale...but the M3W is retro sexy. The Corvette and the SlingShot are a glimpse into the future and the M3W is a glimpse into the past which is equally appealing to me.

I'll keep you posted on the ride date (mid-Octoberish).

Z

|

|

|

|

|

Joined: Jan 2014

Posts: 1,075

Has a lot to Say!

|

Has a lot to Say!

Joined: Jan 2014

Posts: 1,075 |

Zack, glad to hear all went well. I'm in gorgeous Evansville IN for a couple days trying to setup a machine with some of our sub-assemblies, but apparently not the important ones. These are single serving 12oz plastic bottles blow molded neck to neck. Our trimmer separates them and finishes the neck for sealing and then capping. See www.lectroengineering.com and go to MTM and then trimmers. The 2025 model is similar to this clone of our very old model this company brought over from one of their Poland plants. Sorry to digress. Sounds like you have a plan on parts for your M3W. I'm interested to hear about your Slingshot, as I'm sure everyone else here is too. Have a great week.

Dan

|

|

|

|

|

Joined: Dec 2013

Posts: 83

Just Getting Started

|

Just Getting Started

Joined: Dec 2013

Posts: 83 |

|

|

|

|

|

Joined: Aug 2013

Posts: 797

Talk Morgan Regular

|

Talk Morgan Regular

Joined: Aug 2013

Posts: 797 |

|

|

|

|

|

Joined: Dec 2013

Posts: 83

Just Getting Started

|

Just Getting Started

Joined: Dec 2013

Posts: 83 |

I can't speak on behalf of the Centa cush-drive but I have been using LoveJoy type couplings on oilfield equipment drive lines for many years and its surprising how long they last...over a decade in many cases.

Almost every motorcycle on the road has some sort of rubber-based cush-drive. Old Triumphs had 6 rubbers and a three prong "spider" in the clutch hub leveling out the pulses. Old Nortons (and many Asian bikes) have rubber cush drives behind the rear sprockets. Typically, they're worst enemy is age...again, usually decades before they get hard and start disintegrating.

Many people that have built "bitsa" bikes (bits and pieces of several different bikes used to build one "custom" bike) and they make the mistake of using a engine/transmission/clutch without a cush-drive along with a rear wheel without a cush drive, the transmission dies in record time before their very eyes.

I'd rather take my chances with the rubber compensator than mechanical. Ramps, rollers and Bellville washers have a finite life too especially when run dry.

My only concern with the Centa is reports of new vibrations. I think I'm going to build a balancing fixture to see if I can improve on the "as delivered" balance of the unit before installing it.

As far as future rubber replacement when needed, although it won't be fun, it certainly won't be as bad as the initial conversion from the Bellville style compensator.

It's easy to pick a Christmas present for your friends that own M3Ws...compensators, bevel boxes, steering geometry kits, rubber bobbins, timing belts, rectifier/regulators, stators, belts & sprockets, tools, floor jacks, hand cleaner, henways....

Speaking of which, what I'd like for Christmas is to run the M3W division for one year. Their per unit profits may go down slightly but we'd offset it in the volume of reliable units sold.

Z

|

|

|

|

|

Joined: Aug 2013

Posts: 1,562

Talk Morgan Enthusiast

|

Talk Morgan Enthusiast

Joined: Aug 2013

Posts: 1,562 |

I am guessing the Centa drive is run dry , with no grease etc like the previous compensator ?

It does have moving parts so is there any ongoing maintenance ?

Last edited by nippymog; 29/08/14 04:29 PM.

|

|

|

|

|

Joined: Jan 2014

Posts: 1,075

Has a lot to Say!

|

Has a lot to Say!

Joined: Jan 2014

Posts: 1,075 |

Z, thanks for posting these pictures.

I'm going through this in my head trying to visualize the assembly of this amazing bit of pieces. Please correct me if I'm wrong.

Okay, I think the rotor will bolt to the under side of the Centa housing with the spline holding the drive side of it on the S&S crank.

So the larger Centa outer hub is bolted to the motor crank and has some possibility to be out of round, off centerline axis and "may" cause some vibration. It looks like you have a new bolt and washer for this purpose.

I see a bolt pattern in the top of the out Centa housing, but cannot see anything in the pictures to bolt there. Maybe if nothing goes there, Centa used this portion of their aluminum mold for another purpose.

The new shaft would go in from the trans side of the adaptor plate between the compensator housing the bell housing of the trans, of course a new bearing with the new parts. The retainer holds in the new bearing.

The Centa inner webbed part will slide onto the long end of the new shaft and probably be retained by the nut and washer.

Of course the rubber logs will be slid into the inner and outer during assembly. But with the amount of pre-load on the rubber logs, it looks like it could be hard to hold and slide all four rubber logs in at the same time.

What I don't see is any means to "couple" the two halves together for alignment purposes. If there is any miss alignment between the comp housing, trans adapter and bell housing, the unit will not be on the same center axis and could cause vibration.

I know it would be very hard to assembly, but maybe if there were like a trans input shaft pilot bearing in the Centa outer housing just above the crank bolt area. This would allow the inner hub and shaft to pilot from the opposite direction.

I would think that's why some have the new vibration and some don't. It will all depend on the alignment on reassembly.

On your current assembly, there is still the BMW type 6-bolt rubber spider that will allow and compensate for "some" out of alignment. I just see no true way to confirm true alignment of the Centa system. Please enlighten me.

Just for grins and giggles Z, how many dollars are laying on the top of your table?

I look forward to your review and pictures of the installation process.

Have a great holiday weekend.

Dan

|

|

|

|

|

Joined: Oct 2013

Posts: 38

Just Getting Started

|

Just Getting Started

Joined: Oct 2013

Posts: 38 |

I'm with Zackybilly and Mike on this one. We use Lovejoy couplings on most every drive we have out here and they are built to last. The rubber will degrade over time but I think it would be quite some time before they would need replacing, depending on the load put on them.

Karl

Wine For My Men...We Ride At Dawn

|

|

|

|

|

Joined: Dec 2013

Posts: 83

Just Getting Started

|

Just Getting Started

Joined: Dec 2013

Posts: 83 |

Just for grins and giggles Z, how many dollars are laying on the top of your table? That would be $1,400 USD...and I am happy with that. Another dealer quoted more than that for just the compensator alone which did not include rotor, bearings, cir-clips, fasteners, etc. I'm fixing to ring them up again on P&D for a new Bevel Box. Z

|

|

|

|

|

Joined: Jan 2014

Posts: 1,075

Has a lot to Say!

|

Has a lot to Say!

Joined: Jan 2014

Posts: 1,075 |

Just for grins and giggles Z, how many dollars are laying on the top of your table? That would be $1,400 USD...and I am happy with that. Another dealer quoted more than that for just the compensator alone which did not include rotor, bearings, cir-clips, fasteners, etc. I'm fixing to ring them up again on P&D for a new Bevel Box. Z From your pictures, that seems like a fair price. I would have guessed over $2k. Were there any instructions or are you left to fend for yourself? I'm sure there's no manual showing placement etc. I wonder if there has been any new parts catalogs since the two that were posted earlier this year with all the old comp stuff?

Dan

|

|

|

|

|

Joined: Jan 2014

Posts: 1,075

Has a lot to Say!

|

Has a lot to Say!

Joined: Jan 2014

Posts: 1,075 |

Z, thanks for the heads up. I've got my system programmed already to record it for numerous viewings. I've seen a few of the Dream Car series and this one should not disappoint at all. Have a great evening.

Dan

|

|

|

|

|

Joined: Jun 2014

Posts: 28

Just Getting Started

|

Just Getting Started

Joined: Jun 2014

Posts: 28 |

Is there a documented compensator failure? Getting noisy yes but failure?

|

|

|

|

|

Joined: Jan 2014

Posts: 1,075

Has a lot to Say!

|

Has a lot to Say!

Joined: Jan 2014

Posts: 1,075 |

Is there a documented compensator failure? Getting noisy yes but failure? I know many have failed and been replaced, but what does fail mean? I thought this before, but never thought to say anything. The way the Harley style compensator is made, even if the spring pack goes south, the ramps should never pass each other and in theory never stop supplying power to the drive system. But I can see when they get TOO loose that the rattles and torque pulses would be so bad that I too would probably not want to drive the car. But in a pinch it should "never" let one down. If I had 20 or 50 miles to get back home, I would probably drive it home. If I were further away, I may be temped to trailer it back. The compensator is a problem that usually happens gradually and is not usually a catastrophic failure. I know guys with Harleys that have ridden for months with bad compensators just because they didn't have the money to fix it right away. I should have waited for others here with first hand issues with their compensators, but I could not stop my fingers from running wild on the keyboard...

Dan

|

|

|

|

|

Joined: Dec 2013

Posts: 83

Just Getting Started

|

Just Getting Started

Joined: Dec 2013

Posts: 83 |

Dan,

I believe I read on this forum of a compensator failure that took out the alternator (stator)and subsequently, the rectifier/regulator. That was obviously a little more than a clickety-clack.

The beating effect from a substandard compensator takes its toll on the balance of the drive train. Can't imagine it does anything to help the transmission, u-joints, bevel box or the driver, for that matter.

With that being said, as a compensator "loosens up", where do you draw the line? How much is too much? I can make mine hammer (which doesn't require an extreme amount of skill) or I can make mine reasonably quiet just by my driving technique. At that point, the M3W is dictating how to be driven as opposed to how I want to drive it. Naturally, it's going to make the most racket when there are other people around to hear it. When rolling into a reduced speed area, you still have to keep the RPMs up to keep the compensator pinned. To others, I bet they guess my car is stuck in 3rd gear running those kind of RPMs in a "relaxed" area.

On the bright side, I got an official PDF on the Centa install today. Other than the pulling of the engine, it doesn't look too challenging. No the engine pull wasn't included in the document. I like what I'm seeing on the Centa so far.

Z

|

|

|

|

|

Joined: Jan 2014

Posts: 1,075

Has a lot to Say!

|

Has a lot to Say!

Joined: Jan 2014

Posts: 1,075 |

Dan,

I believe I read on this forum of a compensator failure that took out the alternator (stator)and subsequently, the rectifier/regulator. That was obviously a little more than a clickety-clack.

The beating effect from a substandard compensator takes its toll on the balance of the drive train. Can't imagine it does anything to help the transmission, u-joints, bevel box or the driver, for that matter.

With that being said, as a compensator "loosens up", where do you draw the line? How much is too much? I can make mine hammer (which doesn't require an extreme amount of skill) or I can make mine reasonably quiet just by my driving technique. At that point, the M3W is dictating how to be driven as opposed to how I want to drive it. Naturally, it's going to make the most racket when there are other people around to hear it. When rolling into a reduced speed area, you still have to keep the RPMs up to keep the compensator pinned. To others, I bet they guess my car is stuck in 3rd gear running those kind of RPMs in a "relaxed" area.

On the bright side, I got an official PDF on the Centa install today. Other than the pulling of the engine, it doesn't look too challenging. No the engine pull wasn't included in the document. I like what I'm seeing on the Centa so far.

Z