|

11 members (DMC1904, TomS, The Flitting, asterix, BLUE+4, mph, John07, Graham, G4FUJ, Grumpy2, DJC, Vansrv6),

321

guests, and

44

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

Forums34

Topics48,364

Posts813,336

Members9,215

| |

Most Online1,046

Aug 24th, 2023

|

|

|

There are no members with birthdays on this day. |

|

|

|

Joined: Jan 2013

Posts: 400

Learner Plates Off!

|

Learner Plates Off!

Joined: Jan 2013

Posts: 400 |

I just want to stress that I am quite happy with what ever the grease nipple has done. Wether it lasts I have no idea, I have only done a 1000 km after the upgrade.

As far as I know it was done under warranty.

M3W, now!!!

|

|

|

|

|

Joined: Jan 2014

Posts: 462

Learner Plates Off!

|

Learner Plates Off!

Joined: Jan 2014

Posts: 462 |

Is there a tread on where and how to install the compensator grease fitting ?

JV Sclafani

Boca Raton, FL

'13 M3W Metallic Orange Pearl

128CI Steered by Empire - Riding on Ohlins

|

|

|

|

|

Joined: May 2012

Posts: 1,790 Likes: 3

Talk Morgan Enthusiast

|

Talk Morgan Enthusiast

Joined: May 2012

Posts: 1,790 Likes: 3 |

My compensator was changed last September for one with a grease nipple in. When it starts to get a bit noisy I pump some high pressure grease in and that sorts it out. It is now that quiet all I can hear is the BB instead.

|

|

|

|

|

Joined: Aug 2012

Posts: 2,356 Likes: 2

Talk Morgan Expert

|

Talk Morgan Expert

Joined: Aug 2012

Posts: 2,356 Likes: 2 |

So do i

After a big ride i put grease And it is quiet.

|

|

|

|

|

Joined: Jul 2013

Posts: 3,660 Likes: 48

Talk Morgan Addict

|

Talk Morgan Addict

Joined: Jul 2013

Posts: 3,660 Likes: 48 |

So where is the grease going?

I thought it was a sealed unit.

Red Leader

|

|

|

|

|

Joined: Aug 2012

Posts: 2,356 Likes: 2

Talk Morgan Expert

|

Talk Morgan Expert

Joined: Aug 2012

Posts: 2,356 Likes: 2 |

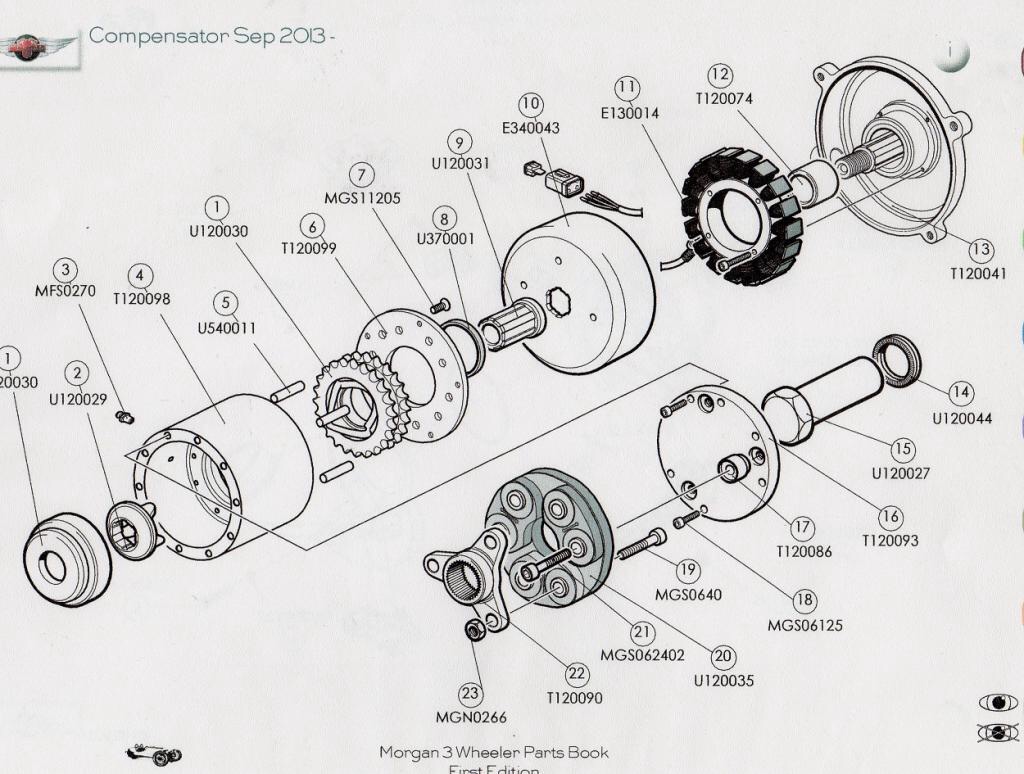

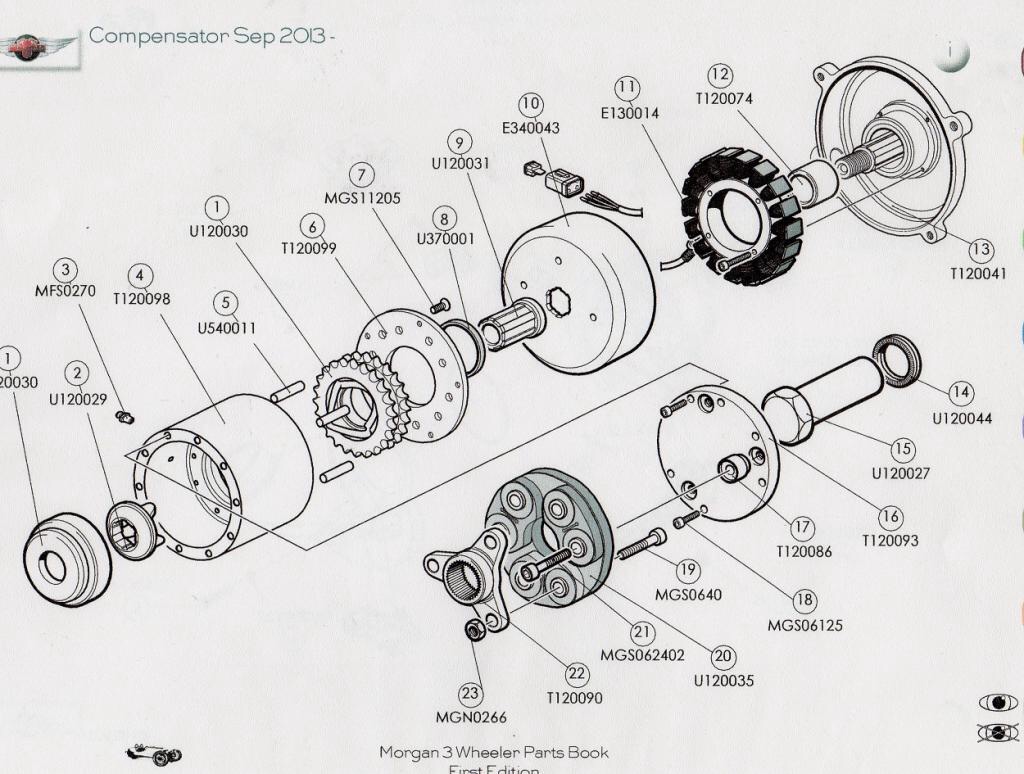

p In the cylinder on the left

Last edited by atalante83; 21/07/14 04:06 PM.

|

|

|

|

|

Joined: Oct 2012

Posts: 6,538

Talk Morgan Sage

|

Talk Morgan Sage

Joined: Oct 2012

Posts: 6,538 |

Wow - what an interesting diagram!!! thanks for posting!!

Neil

|

|

|

|

|

Joined: Aug 2012

Posts: 2,356 Likes: 2

Talk Morgan Expert

|

Talk Morgan Expert

Joined: Aug 2012

Posts: 2,356 Likes: 2 |

|

|

|

|

|

Joined: Aug 2012

Posts: 2,356 Likes: 2

Talk Morgan Expert

|

Talk Morgan Expert

Joined: Aug 2012

Posts: 2,356 Likes: 2 |

Is there a tread on where and how to install the compensator grease fitting ? Number 3

Last edited by atalante83; 21/07/14 05:20 PM.

|

|

|

|

|

Joined: Jan 2014

Posts: 1,075

Has a lot to Say!

|

Has a lot to Say!

Joined: Jan 2014

Posts: 1,075 |

p In the cylinder on the left My question has always been this, why have all the complicated compensator when they have the BMW type driveshaft torsional damper, item 20 that on my quote picture is cropped on the side, but is the lower right part with a bunch of holes in it. I was thinking that they're obviously strong enough for a BMW sedan to use on their drive shaft and one has more than enough to work on a M3W, why not stack three of them keeping each as a separate in series stack? I think that would be a great compensator without any moving parts, so to speak. No grease and self aligning. The motor crank would stabilize the one end of the stack and the flywheel for trans through the adapter plate bearing would hold true the clutch end. I think there would be more than enough strength as well as shock absorbing capabilities to do the jog. Then Centa is still rubber inserts being pressed and this would just be rubber twisting. Any thoughts on this as an option? It would sure be cheaper as these rubber couplings sell on ebay for under $40 each. So three would be $120 and bolting them together shouldn't cost much. The motor plate on the rotor could be tapped to bolt directly to it on one end and the other end already has the rubber ring and adapter that slides over the trans flywheel input shaft. It seems like a no brainer to me, again thoughts?

Dan

|

|

|

|

|