p

In the cylinder on the left

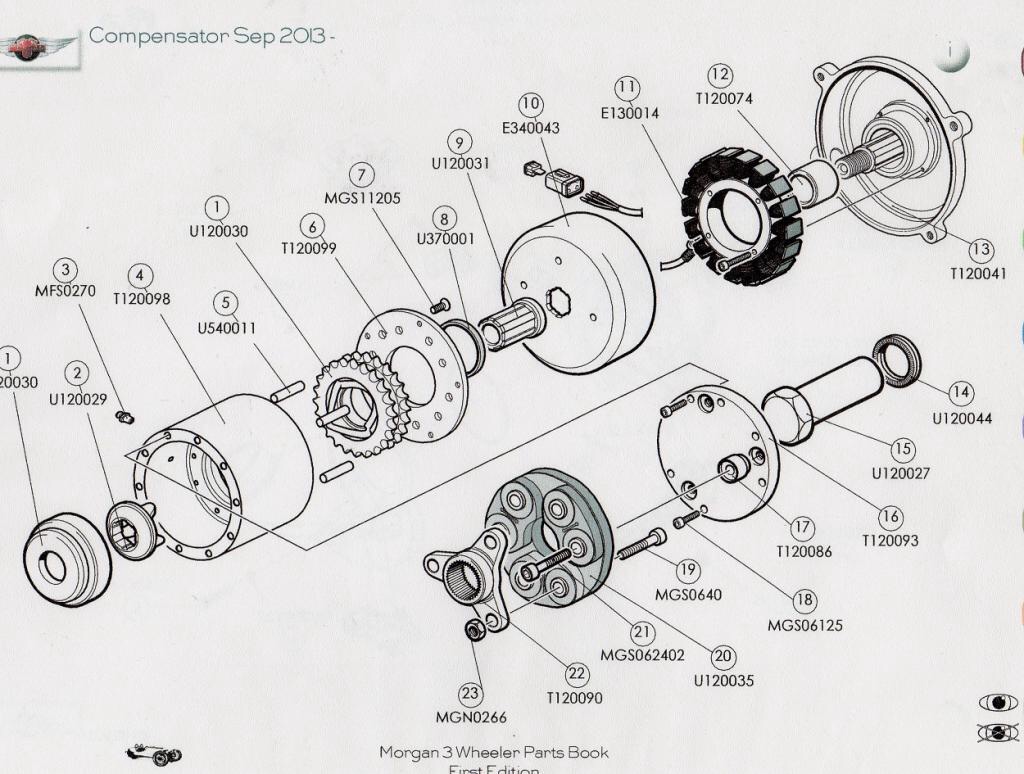

My question has always been this, why have all the complicated compensator when they have the BMW type driveshaft torsional damper, item 20 that on my quote picture is cropped on the side, but is the lower right part with a bunch of holes in it.

I was thinking that they're obviously strong enough for a BMW sedan to use on their drive shaft and one has more than enough to work on a M3W, why not stack three of them keeping each as a separate in series stack? I think that would be a great compensator without any moving parts, so to speak. No grease and self aligning. The motor crank would stabilize the one end of the stack and the flywheel for trans through the adapter plate bearing would hold true the clutch end.

I think there would be more than enough strength as well as shock absorbing capabilities to do the jog. Then Centa is still rubber inserts being pressed and this would just be rubber twisting.

Any thoughts on this as an option? It would sure be cheaper as these rubber couplings sell on ebay for under $40 each. So three would be $120 and bolting them together shouldn't cost much. The motor plate on the rotor could be tapped to bolt directly to it on one end and the other end already has the rubber ring and adapter that slides over the trans flywheel input shaft.

It seems like a no brainer to me, again thoughts?