Update 26 - Chassis rebuildThe race cars had to take a bit of a back seat for the last 12 months (I can't believe it's been that long!!)

Last week saw enough time to get round to kicking off works to get these cars completed and back on track (pardon the pun).

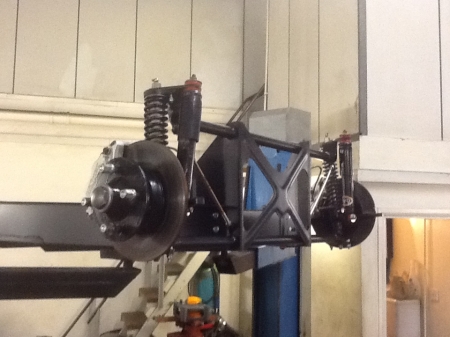

As we have pretty much all the parts - it's a big heap - we started by building up the new chassis with the new parts we have and with the usable parts off the front end of the blue and white car.

This chassis is built to the latest GEE racing spec with a strengthened cross head mounting, larger re-enforcing gussets at the bulkhead, slightly thicker gauge metal over the rear axle mounting area and a cross head frame set to 1 Deg neg camber as standard along with more caster rake. Thanks to GEE for sorting this out for us.

Now that the basic front end has been built up with the loose parts we set about stripping down the rest of the front end of the damaged car. All broken parts are going to be replaced and currently we have a mind to keep the back end of the 4/4 frame to turn into a mog style trailer seeing as we have all the parts needed. (another fun project for a later date).

As you can see there is plenty to strip off - it always saddens me to see the damage - especially the exhaust it was a real work of art.

Bonnets with the remainder of the N/S wing - it took the brunt of the impact.

You can really see the extent of the impact damage to the frame in this picture, both front legs are damaged but you can clearly see the N/S is damaged really badly with multiple kinks inboard. Luckily all the damage is restricted to in-front of the bulkhead which is probably down to it being a weak-spot in the chassis/body strength.

The engine is undamaged and this has been dropped out along with the Omex 200 ECU to be bolted into Woodstock. The Blue and White car will be fitted with the Omex 600 ECU along with the the re-built full face engine running throttle bodies.

The next step was to separate the body tub from the damaged chassis such that the old chassis can be stripped down fully and transplanted onto the new chassis.

Always a bit interesting this step...

We use one of our lifts to pick the body of the chassis which is resting on a heavy duty dolly (we've bee rolling the cars round the garage for the last year!!)

Mogs are such a simple set-up the breakdown process is really simple. You can see the whole car laid out in the pics above. It's the re-build process which is going to eat the time!!

We've put the chassis to one side so it can be stripped down - the new chassis is on the dolly ready to start accepting parts.

Whilst all this is happening, I've managed to source a possible hard top for Woodstock which we'll be picking up for a test fit in a few weeks.