There has been some forum traffic recently about power steering. I have been fortunate to have owned a 2001 Plus 8 from new and I upgraded it with a Mogsport handling kit some years ago. This improved the steering significantly and greatly added to my enjoyment of the car. However, when I moved house, access to the garage in my new abode (which had greater garage capacity�one of the reasons for the relocation) involved a sharp (basically 180 degree) turn on my drive. I found this tricky to negotiate at parking speeds but found that once expert I could get the car undercover after only a 5 - 6 point turn. The whole thing just became too much of a pain and as a consequence I was using the car less and less.

So, when an established, approved Morgan dealership / service agent advertised an electric power steering retrofit for classic models, I thought this would be the thing for me. I made enquiries and was reassured by the genial and readily available dealer that a) this was a professional package that they had developed over time on their motorsport cars to the point that they felt they could market it and fit it to paying customers, b) the electric motor used was exceptionally durable, maintenance free and could be fitted with a minimum of changes to the vehicle structure, c) should any unforeseen problems with the system arise in the future, parts would be easy to obtain because it was used on a number of contemporary mass produced cars.

It was explained that the steering column would need to be modified and as a consequence it would not be collapsible or height adjustable, but this seemed to be a reasonable price to pay (talking of price the whole thing cost over two thousand pounds fitted).

Once installed the car was transformed. The electric assist was only active at speeds of less than 30 mph. The car could then be effortlessly manoeuvered at low speed, such that I was able to fit a 12 inch leather Mota-Lita steering wheel and could still steer during parking with just one finger. However, at speeds of over 30mph the car felt and handled exactly the same as before. The level of assist was progressive such that as the car sped up, the assist gradually became less. I also noticed that on uneven surfaces, there was damping of the kickback to the steering wheel when negotiating lumps and bumps, making the ride feel smoother. I congratulated myself on a wise purchase.

Four thousand miles later, I drove to the 2012 Le Mans Classic. On the way back I was caught in a downpour whilst approaching Calais. The power steering cut out. I posted details at the time on TalkMog but to cut a long story short (no pun intended) by the time the car eventually made it back and was sent to the dealership for a once-over, everything was working again. The elusive owner of the establishment (racing commitments frequently impaired his ability to return my calls) informed me that he had assured himself that the system was working, all the holes that had been drilled in the bulkhead (WTF?) had now been sealed with waterproofing and that this episode was due to a freak electrical short due to excessive water ingress. To be fair, this was done FoC.

All was then fine until this year�s LMC, when again there was a downpour of biblical proportions on the way home. The power assist was lost but this time it did not come back. The owner of the dealership was now even more engaged in motorsport, indeed he made Lord Lucan appear relatively available. His staff eventually explained to me that a) the chap who they had subcontracted the work out to (subcontracted? Again WTF ?!!) had disappeared off the face of the earth and b) they had no idea of the origin of any of the parts used or which mass produced vehicles, if any, deployed this particular system. Not exactly what I wanted to hear. They did however, very kindly manage to source another electric motor which, after several days, they found lurking in their racing parts / spares store. I am guessing that this was the only such spare motor in existence. They posted this up FOC, for which I am grateful.

Electric steering assist works by removing part of the steering column and inserting a new section in its place that is connected by gears to an adjacent electric motor. This motor is controlled by an ECU, which senses the speed of the car and the rotation of the steering column. As the wheel turns the ECU adjusts the assist the motor delivers to the column. This is adjustable so that the degree of assist can be altered. The ECU and the electric motor are housed within the cabin, the steering rack is unaltered so that the original ratios are retained. When the system is disabled the direct mechanical connection between steering wheel and steering rack remains intact and there is therefore no discernable difference from that before the system was fitted (as opposed to a hydraulic assist system).

In this description I will refer to the steering wheel end of the composite steering column as the proximal end and the steering rack end as the distal end.

The motor looks like this with the proximal end of the shaft (that connects via a modified segment of column to the steering wheel) on the left of the picture and the distal end of the shaft (that connects via a modified and shortened steering column to the steering rack) on the right of the picture. There are no discernable markings enabling identification of the origin of this motor so that a replacement cannot be sourced:

With the steering wheel and proximal part of the steering column disarticulated

the motor can be seen in-situ within the driver�s footwell and looks like this:

Nasty surprise number one was that I found that a huge U-shaped hole had been cut (unnecessarily) into the bulkhead to allow the distal end of the electric motor / proximal end of the remaining modified steering column to pass through. The distal shaft coming out of the motor has a female end that fits onto a male spline that forms the proximal end of the now shortened and modified steering column under the bonnet. This spline, disarticulated, can be seen here, photographed under the bonnet, the U shaped hole in the bulkhead is visible in the top left corner of the photo:

The additional �waterproofing� that had been applied by the dealership when the system failed first time, turned out to be a piece of old rubber car floor mat which had been cut to shape and glued to the bulkhead to surround the shaft as it emerged. Water easily came through this �seal� and had cascaded onto my legs whilst driving in the heavy rain and indeed it was this that burnt out the electric motor causing the fault. Additionally there were a number of holes drilled into the bulkhead in order to attach the metal template holding the motor onto the bulkhead.

Nasty surprise number two was that there seemed to be a plastic spacer between the male and female joints of the spline. When the column was disarticulated in order to remove the failed motor, this plastic spacer disintegrated. Enquiries were made of the dealer, MMC and various other companies, nobody was aware of this plastic part and it proved impossible to source another one. The damaged spacer can be seen here:

It turns out that the proximal end of the modified steering column under the bonnet, that comprised the male part of this spline, was non-hardened steel. The fit between the male and female parts of the spline was poor, i.e. there was a gap and this had seemingly been addressed during fitting by injecting some form of resinous plastic into the joint. This had hardened to form the spacer. If degeneration of this plastic / resin seal had happened whilst driving, then the play between the two ends of the spline would presumably have seriously affected the steering.

In order to fix this it was necessary to build a new steering column for attachment to the rack, machine the proximal end into the male part of the spline for connection to the power steering motor and then harden the metal. This has now resulted in a snug metal-to-metal connection between the proximal end of the steering column and the distal end of the (replacement) steering motor, which is much safer than before.

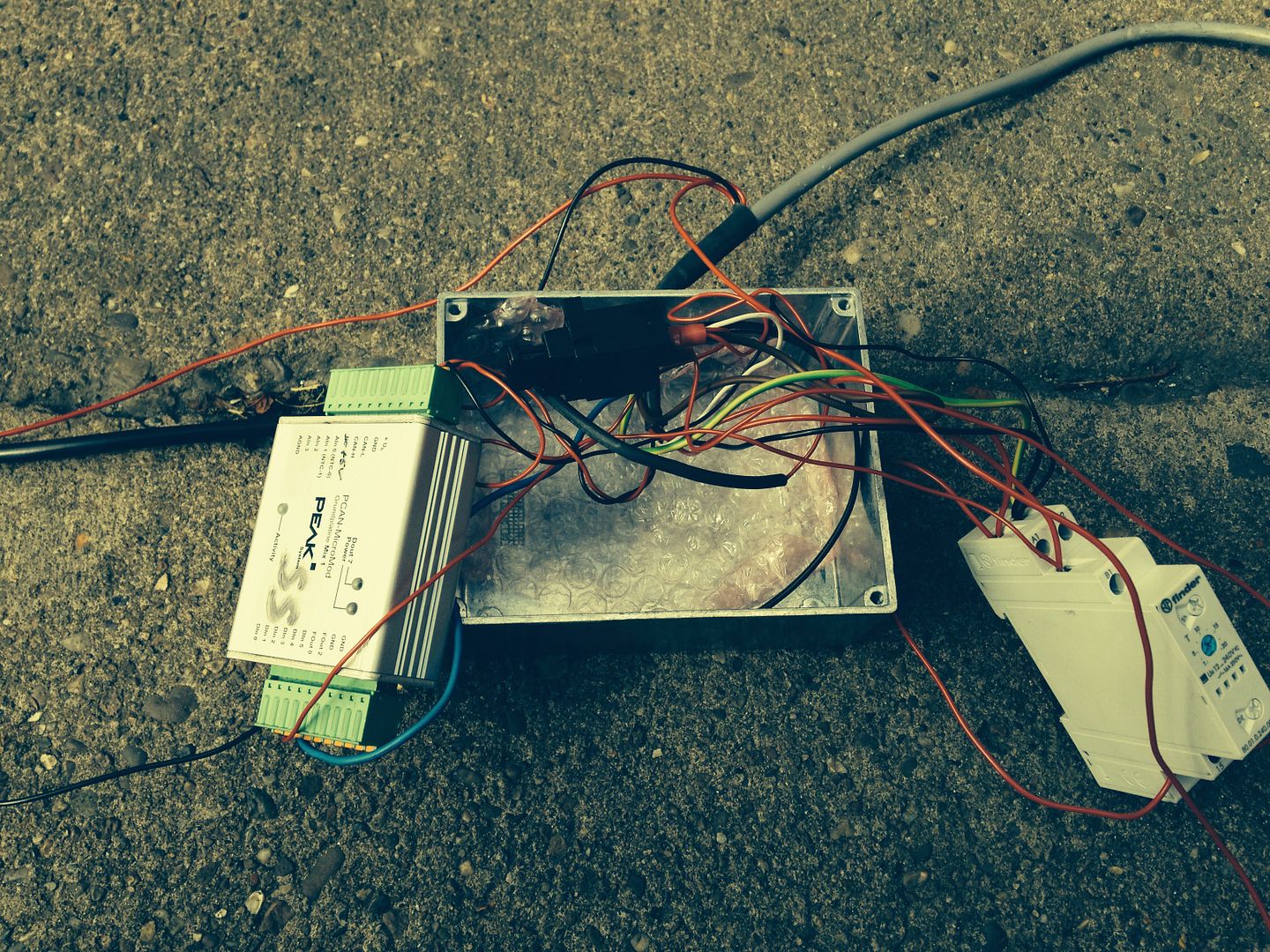

Turning to the �ECU�, nasty surprise number 3 was the quality of the wiring. It was all domestic, non-shielded wire. The wire connecting the control box to the speed sensor on the rear axle is domestic speaker cable. This is excessively long and had been coiled up under the passenger footwell carpet as seen here, on the left, together with the opened box containing the �ECU�:

The control box itself is attached the dashboard using Velcro:

Inside the control box, wiring is all single stranded domestic computer wire.

The cut off at higher speed is achieved by nothing more than a domestic fuse (seen on the right of this picture), which acts as a potentiometer and can be adjusted by using a screwdriver:

There is a cable coming out of the box, which has a connector for attachment to a laptop. The software for adjusting / recalibrating the steering assist however is not obtainable, according to dealership. The standard of the wiring of entire the loom for the system can be assessed by a look at this laptop connector here, exposed wires can easily be seen:

I seriously considered restoring the original steering set up and dispensing with the power assist although that would have entailed either commissioning an entirely new steering column or harvesting a spare from a donor Plus 8 (unlikely). Instead I had the faults in the modifications corrected. The final result after all of this has been significant improvement of the previous system but at some cost. A replacement motor has been fitted, a new spline has been manufactured connecting the motor to the steering column distally. The whole wiring loom for the system has been replaced. The attachment of the motor to the bulkhead and the hole in the bulkhead through which the steering column passes have been re-waterproofed and fitted with a proper seal:

My thanks have to go to Trevor (auto genius and previous Morgan owner) at the extremely helpful Bingham Auto Care who has diagnosed the faults, organized machining of the new column, berated folk at the dealership and re-wired the loom.