Sorry things have been a bit quiet, unfortunately sometimes life gets in the way.. anyhow, this weekend back to business!!

General Update

General UpdateUnfortunately we have run into a few delays over the last few weeks.

EnginePEC the conrod manufacturer has had some delays in importing the Zetec E rods we need. It's a bit annoying as we went with PEC for a couple of reasons, one of which was turn around time. If we knew this delay would exist we would have gone with another supplier, Arrow/Cosworth or Carrillo. Anyhow, latest news is that they are coming through and we should have the engine sometime next week. We've also been resolving the Flywheel and Clutch combo, initially we were going to use a modified 1800zetec flywheel with a Zetec clutch and longer thrust bearing. However when the donor flywheel was checked the Clutch bolt holes were a couple of thou out and would cause extreme vibration at the RPM's we're looking at. Plan B was to use the modified TTV Zetec flywheel and Pinto clutch on my existing CVH engine. Unfortunately this flywheel does not have a Crank position trigger pattern milled into it, so in the end "it's no dice" on that front. Now we are back to open options I'm inclined to go with the "right" option, so I'm thinking of going for a TTV Zetec Superlight Flywheel with either a 7.25inch or 5.5inch clutch pack. Ideally a twin plate ceramatallic 5.5 inch package to keep rotating masses down. Anyhow, jury is still out on this, tbc next week.

AxleHaving shipped the back Axle up to JB Engineering three weeks ago, I'd not been aware that they were in a 2 week shutdown for charity work. An honourable task to be delayed by and now they are back they are turning around the axle pronto but this only started Tuesday last week when they returned. ETA on this is likely to be next week as well....

Could have the engine and axle back at the same time!!

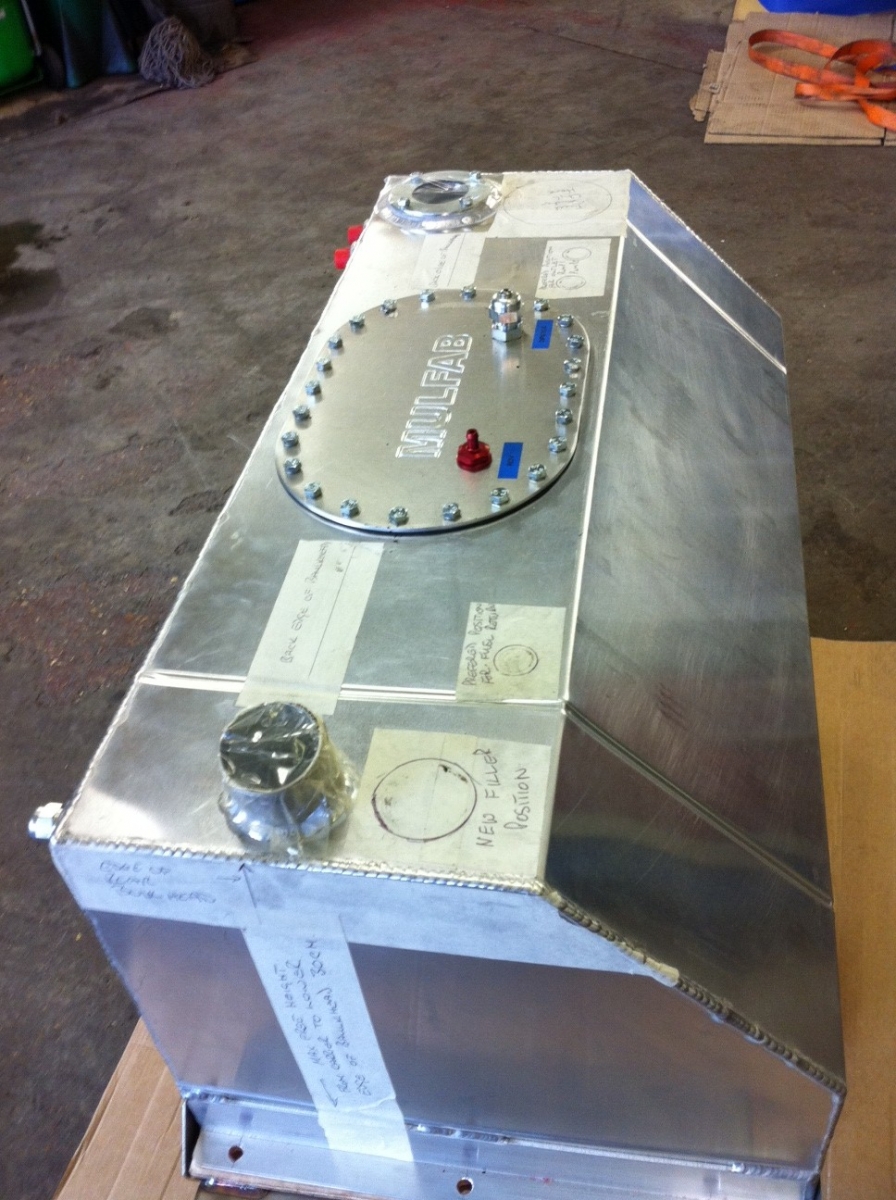

Main Update - Fuel tankThis week we lifted the car back off the trailer and went about fitting the tank. We quickly ran into a few snags. The tank is, in outline "the right shape", just the filler and the fuel sender unit is in the wrong place for our car. Possibly this is suited to an earlier 4/4. Anyhow you can see the problem below.

So... following a quick phone conversation to Peter at Mulfab (who was very accomodating) we spent the rest of the day revising/remarking the layout for a replacement to be made. In addition we designed the swirl pot we need which can be used now for carbs but also in the future if we go injection.

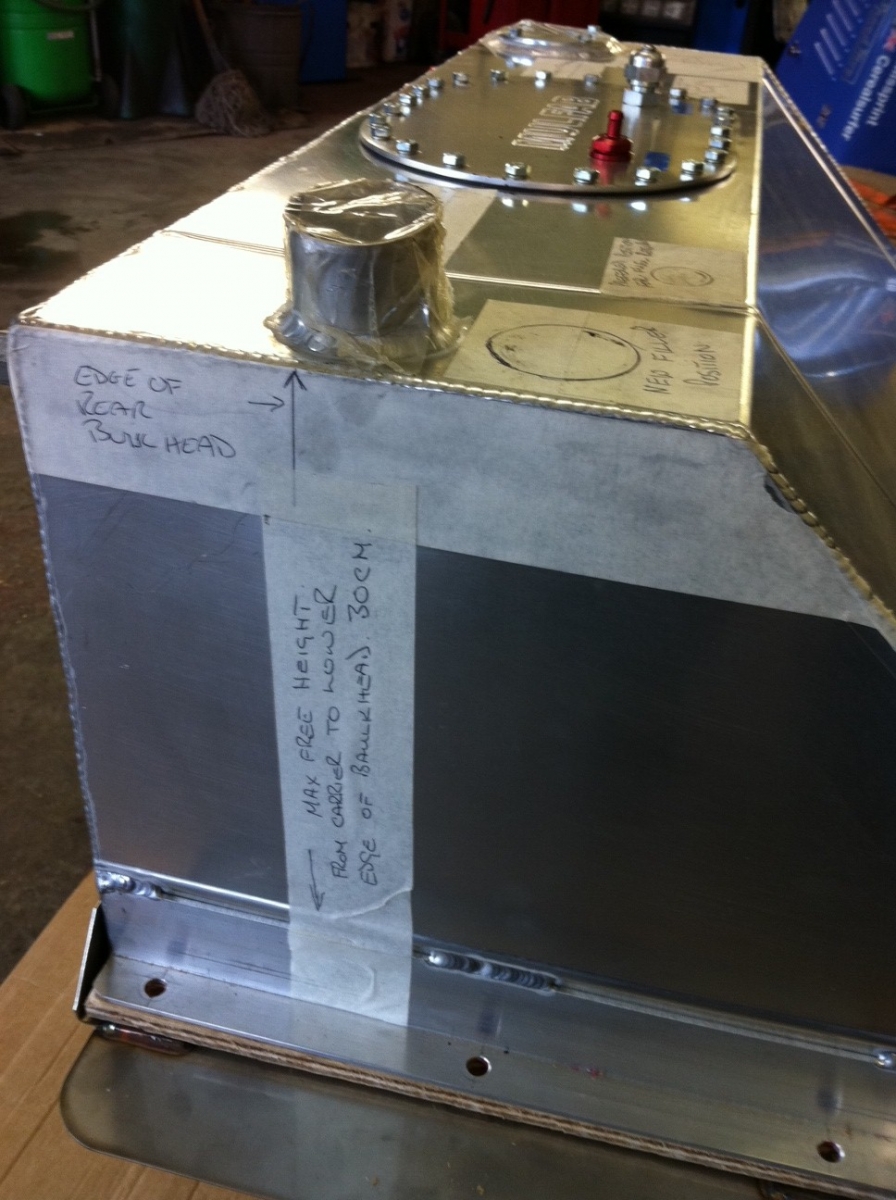

Firstly we needed to validate the outline measurements of the frame. We unbolted the tank from the frame and mounted the frame in position. Using an extended square we measured the limitations of the volume of the space. Once checked we knew that the tank itself would fit into the available hole using the carrier. The problem seemed to be specfically the location of the filler and fuel sender unit. The filler snags the rear frame of the driver tub and there is not enough height for the fuel sender unit to protrude above the tank - as the tank would almost touch the top of the evailable hole.

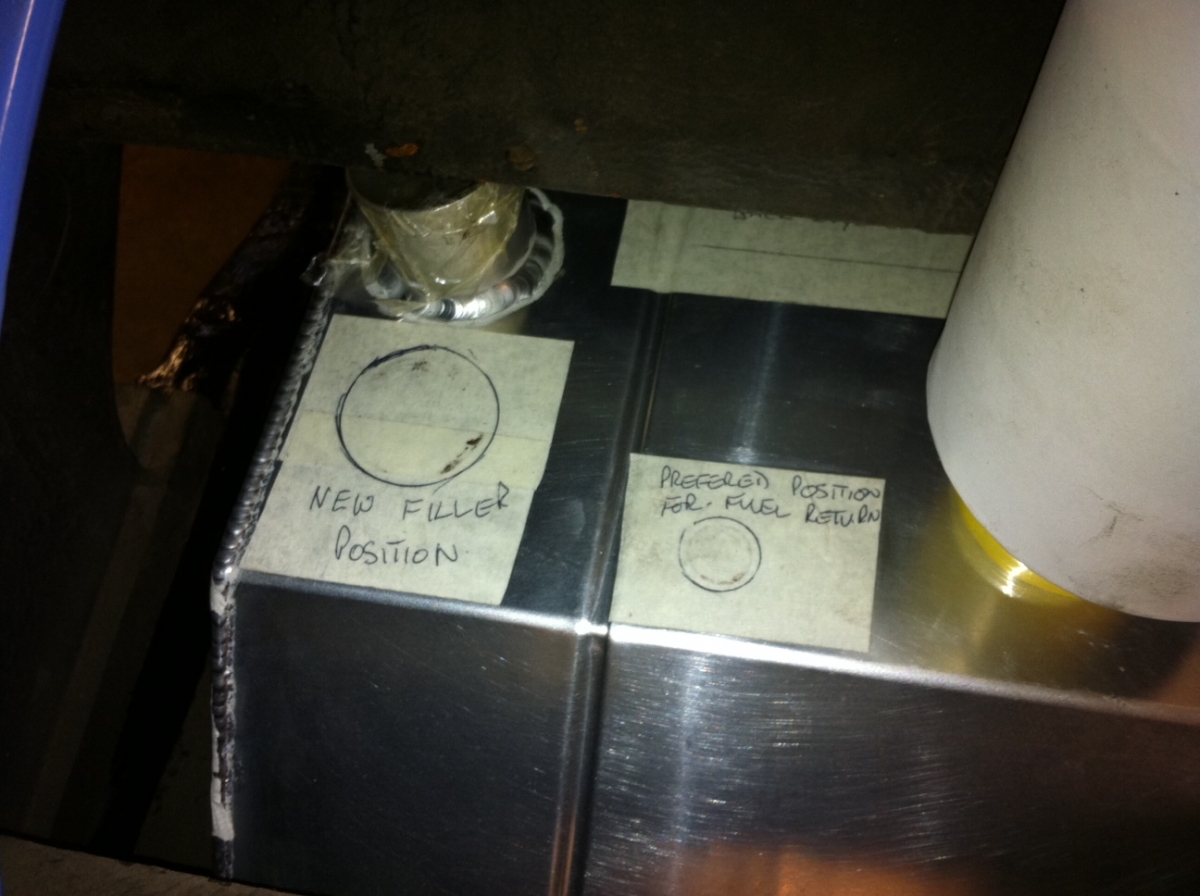

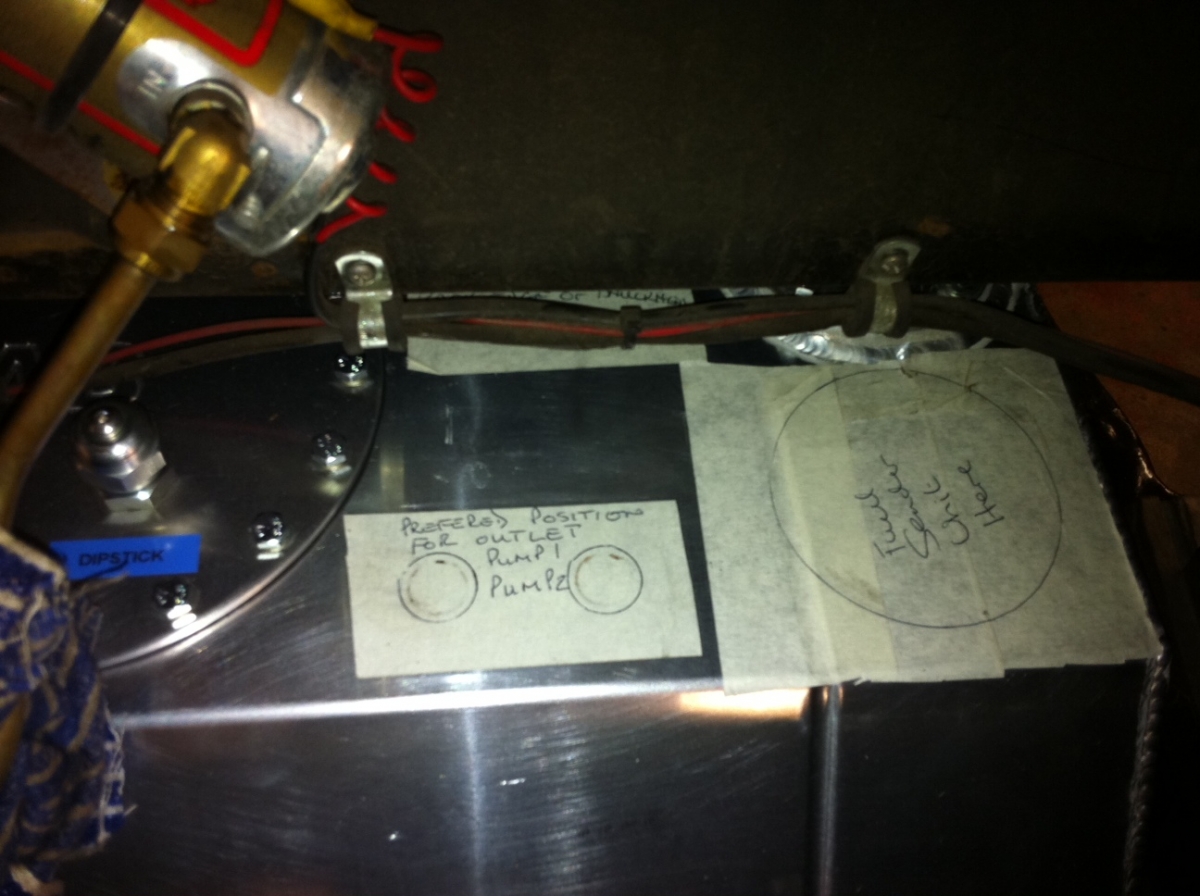

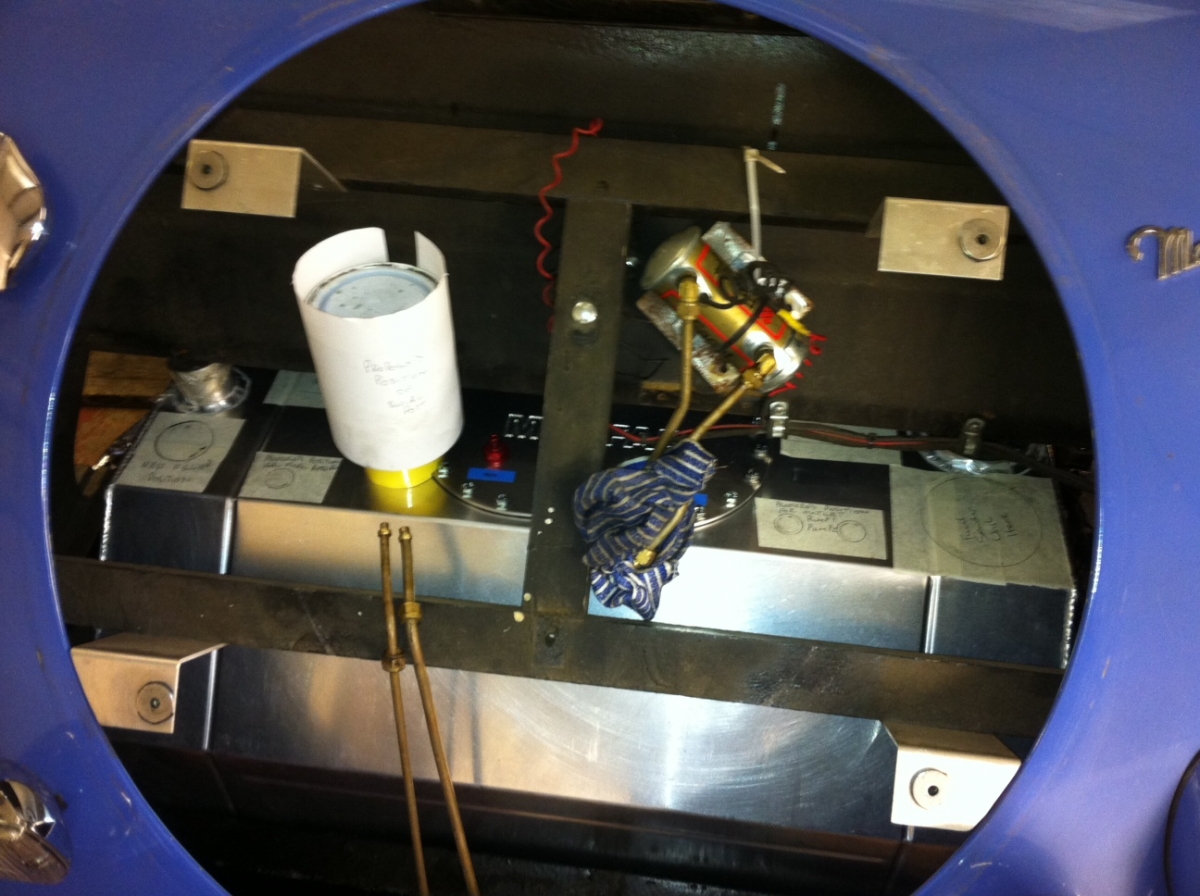

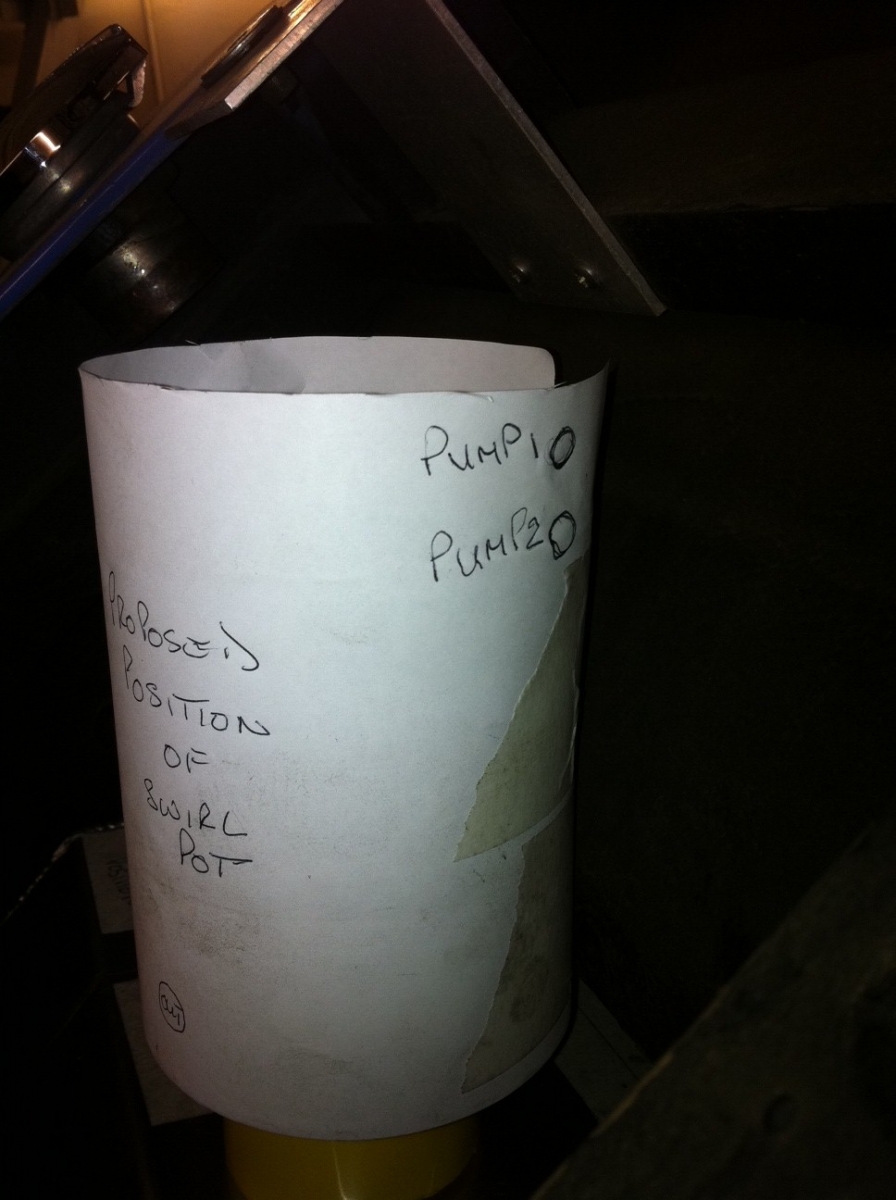

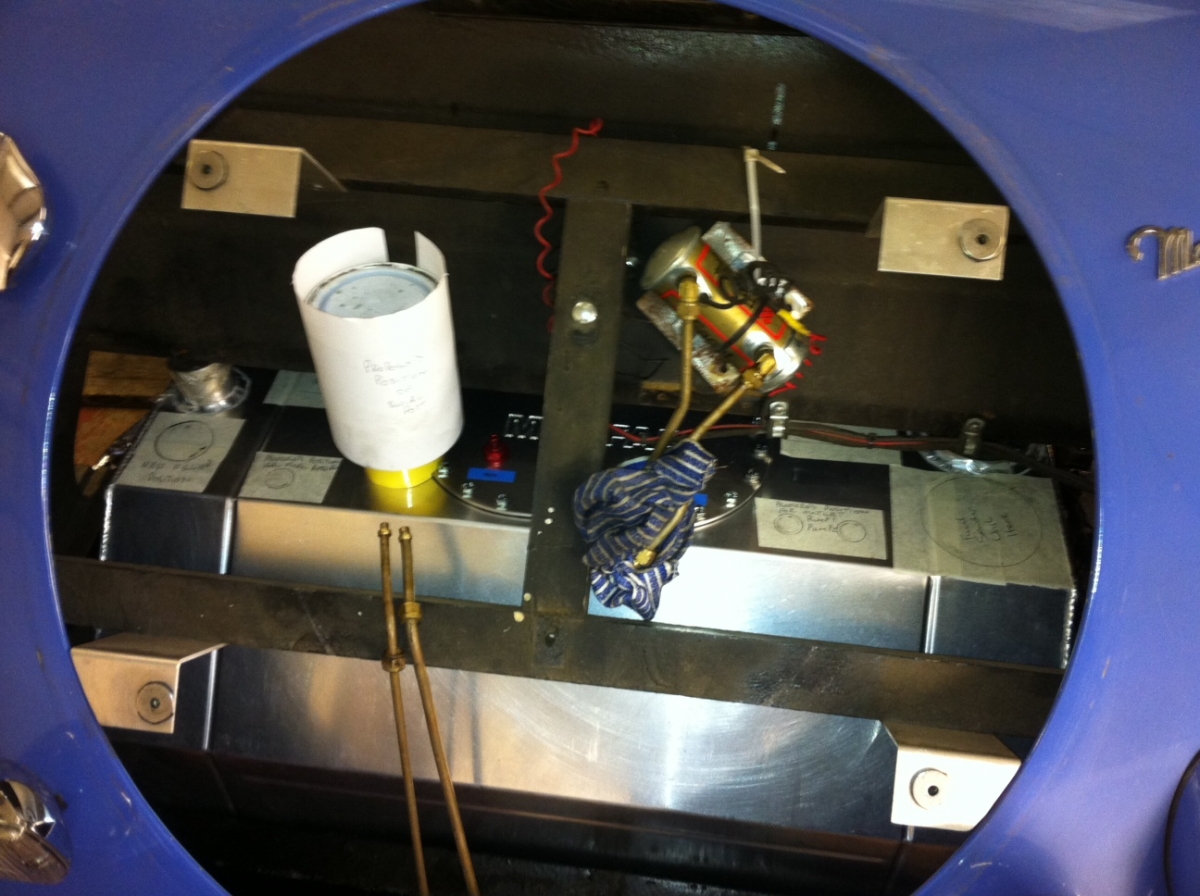

We re-mounted the tank to the frame and held it up on an axle stand and used masking tape to mark out the limitations and revised attachment fitting locations. As it will have to be a new tank, we have also taken the opportunity to mark out ideal locations for the LH and RH fuel pick up connectors and the fuel return connector. These have been marked out to be ideally placed for a rear mounted 1.2lt swirl pot. (the white paper cylinder).

We had been advised to put the swirl pot where the battery used to be, behind the seats, whilst this probably works, it doesn't help accessibility and would require quite a lot of pipe-work..... so we had a look to see where else could work. In the end we've plumped for a swirl pot just over a litre above the LHS of the tank. If we moved the connectors to the top of the tank this would result in much shorter runs of pipework and easy access to both the swirl pot itself and all three of the fuel pumps.

Our proposal is the following:

On the RHS at the rear of the swirl pot there are the two lift feeds coming from the RHS top surface of the tank. The output feed to the engine is at the lower front (you can see the existing metal fuel pipes sticking up). The overflow from the top of the swirl pot can feed back down into the return just to the LHS of the swirl pot. The remaining feed that we won't need right now but will do in the future is the injection return. It's the second of the metal fuel pipes sticking up and will also have a feed back into the Swirl pot.

The net result is the following outline:

Next week could be a big week with many things all happening at once, the axle and engine could be ready to return. The Fuel tank shortly after.

We need this to happen as we only have 7 weeks until Race 1 (5/6 May) and once all this hardware is fitted the Librahds exhaust needs making/fitting. Once this has been fabricated the engine can be started for the first time and the 3D ignition ECU and carbs need sorting.

It's looking like things are going to get busy!!!