Another weekend and another update

So.. outstanding jobs to do

- Source & Install alternator

- Swap miss-labelled starter and install

- Trim ignition leads and install

- Final fit fuelling lines

- Swap out the 36mm chokes for 40mm chokes

- Remove old (RaceTech Coil) and re-wire for Ford Coil (they provide a replacement plug for this)

- Sort out coolant pipes

- Fabricate Idler pulley bracket and install idler

So first-up Fuel plumbing.

So you've seen the layout before, we decided to down-size the bore of the piping to keep the flow rate up. Using the connectors I had sourced we were also able to confirm routing and final combinations of ends. Having measured the routing we bagged up one pipe package at a time and popped down to the hose company and had them made up. You can see the result below. All we need to do now is use the switched feed (from the fuel toggle switch on the dash) to a local relay to power up the pumps. But it looks great. You can also just see we had to fabricate a fuel filler neck.. otherwise we would be hunting around for a pipe for ages.

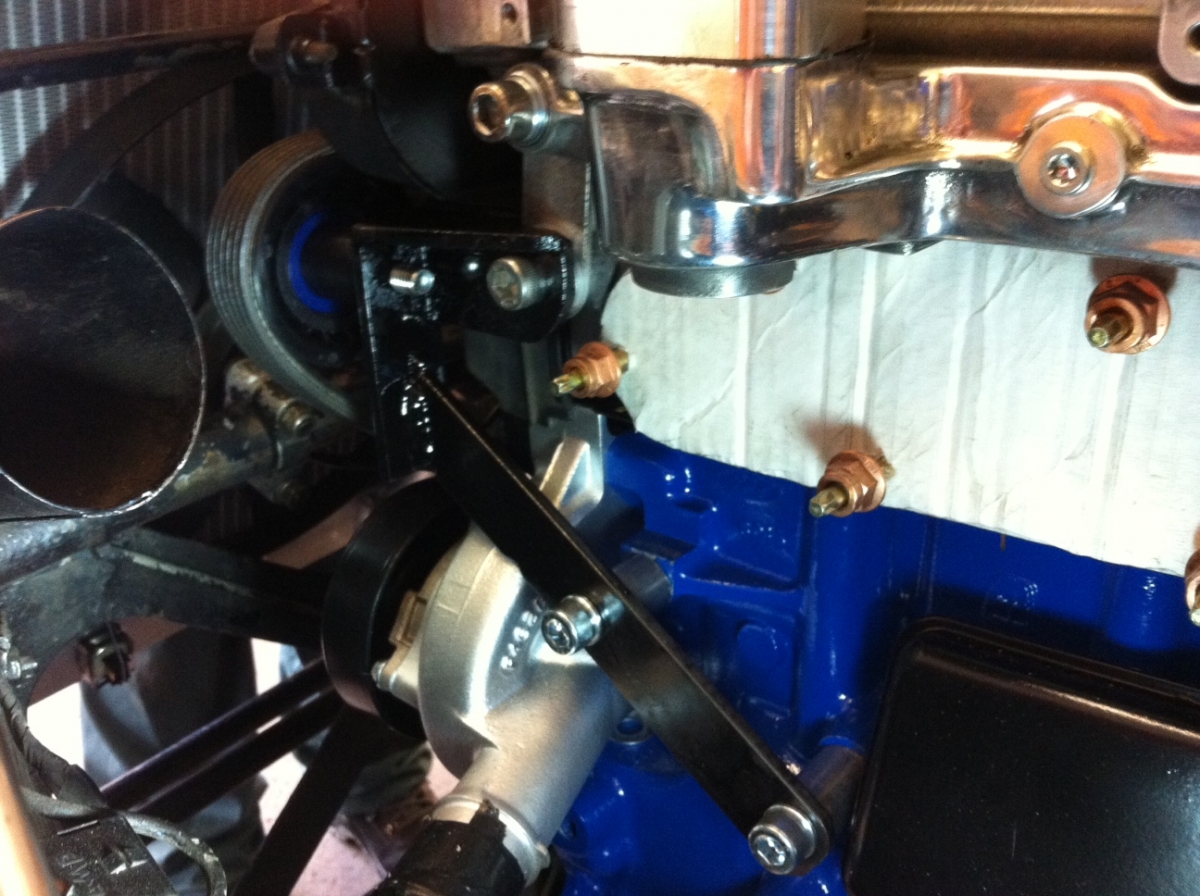

Next up fabricating the idler pulley bracket.

I've looked at all the options on the market for this and seen most of them in situ on cars. All have pro's and con's. I'm a big fan of keeping the cam wheels & timing belt covered. After all you don't want a stone killing an expensive engine. You'd be pretty disappointed. Luckily on the CVH Perspex versions had been made and I managed to get my hands on one. For the Zetec E this has not been so easy. Possibly because on Ford installations the lower part of the pulley cover is actually the engine mount.

Anyhow, one school of design option uses one of the bolt holes just above the water pump to secure the pulley wheel in the correct position. Unfortunately this means you need to removed the cover - looks fancy - not very practical.

Second school of design uses the bolt holes on the engine mount to put a horizontal bracket across - advantage is you get to keep the cover on, down-side is that it bends and squeals like hell, even when re-enforced.

So our decision was to use the Raceline bolt mounted approach (school 1) and mount it on a bracket (but not how School 2 do). So we decided fabricate a bracket which uses several spare threaded bolt holes already on the engine using 5mm steel. Having come up with the design I popped up to the local Forge (yes we have a old-school village forge locally to us) who do heavy custom engineering jobs (like make beacon tower tops from the old Armada warning system). Anyhow.. they are a local metal supplier and they've been friends of the family for ages.

So whilst I was up there getting some steel lengths I saw their friction saw (this place is full of serious metal tools). Given the friction saw blade is about 8mm thick and about 50cm diameter I though you'd find this funny... it clearly takes some getting going.

Once back after some work we came up with the following... I don't think this is going to bend. Look top left of the engine.

I don't have a photo of the Alternator install.. in the end I used a Raceline Alternator mount and a Brise Mitsubishi small form factor Alternator (which self disengages) designed for a BDA with an 80mm lightweight Aluminium pulley to gear it down. I suspected that the top mount could be a problem as I'd read about install problems on the net.. the recommended Alternator from Raceline is just too big for a Morgan.

In the end, the bottom mounts were ok and the unit was perfect in size. The top adjuster bracket from the kit was a waste of time though.. luckily we have a load of old arced adjusters from old Alternator installs which fitted perfectly as they have a dog leg in them. Sorted.

It looks a really smart install.. just need to run the wiring from the N/S to the O/S to get it connected.

Whilst on this side of the car I also whipped the carbs apart to put the larger chokes in.

Another faf was the ignition leads, these were from Retro Ford. As the cam cover is new it clearly needs special lead ends to seal the holes... so I picked up a set of 8mm race leads in blue. As Retro Ford specialise in old-school conversions their leads are designed to be run down through the inlet manifold 2 leads between 1&2 and 2 leads between 3&4. This means you hide the coil under the inlet manifold ala BDA. On this departure from the stated strategy, I wanted to keep the coil on the back of the engine, where Morgan as Morgan have a recess in the bulkhead here and it's easy to access for maintenance. We have the ITG filter to contend with every time if we put it under the manifold. So this meant I had a bunch of Ignition Leeds all the same length for a variable length install... well that looked rubbish. So having borrowed a set of Lead fabrication crimpers (these things are seriously expensive) I took apart 3 of the leads, shortened them and re-assembled them shorter to make a uniform curve onto the coil.. much better.

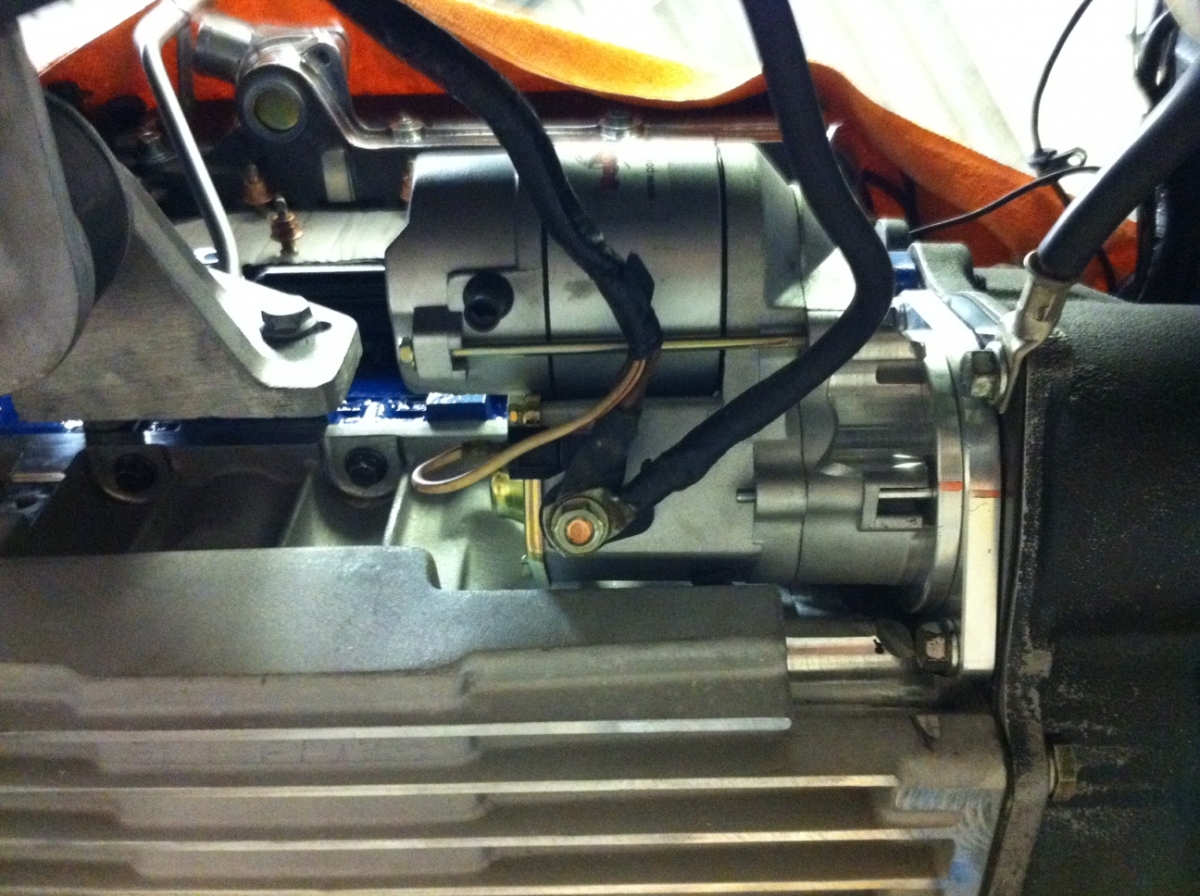

The last job of the day was fitting the starter... again this was a time consuming job... just bolt in.. nope.!

As the raceline starter we had been supplied was wrong last week.... Right part number on box and on sealed packet which the starter was in.. but wrong part in the bag! We could not check the starter hole in the dust plate. Dag-nam-it... it would be slightly different... if we'd used the other dust plate we had it would have been a no-brainer to get in.. but as it was we were be-jiggered if we were going to drop the engine out of the way to swap it.. in the end we used a special air powered needle nose band sander to enlarge the hole. We also ended up "adjusting" the sump slightly to get clearance in all the right places.. you can see how close it is - and this is a small form factor geared down starter!

Unfortunately I have not been able to work on it today, but dad's sorting out the coolant system, the fuel & Alternator electrics and the coil harness. Unfortunately the Oil pressure sensor and the Oil temp sensor had not arrived Friday so these will go on next week. On Sat I need to take it to get it's manifold made.