Update 32 - Inner bay panels and engine intake spacingSide & Rear wingSo over the last couple of weeks we have been progressing with a number of small jobs. Fitting a new body side panel as well as fitting a new rear wing. Both worked out well and were easily completed.

Inner Bay panels

Inner Bay panelsNext up was getting the bay panels sorted as the engine packaging with the new intake needed to be considered and completed prior to getting new bonnets made.

So having dug the panels out of the parts store (seems like we have a complete car in bits sometimes). They were dummied onto the car with g-clamps.

Additionally, the damper blade mounts are also located using holes in the chassis and the inner bay panel base, so these along with the brake reactions bar lower mounting point could all get sorted.

The damper blades requiring notching to allow for the larger Mulfab HiSpec 4 pot callipers to swing round on full lock.

On the O/S the steering box could also be dummied on and the mountings drilled.

This sorts out most of the front end basics.

This was all set to be de-constructed and painted ready for final fit.

Hanging up overnight drying.

Air intake and throttle body packaging

Air intake and throttle body packagingOK, so one of the frequently asked questions on here is the packaging issues around throttle body fitment on 4/4's. We have seen in the past the challenges I've dealt with when fitting DCOE's. Whilst it is possible to get them packaged under a standard bonnet, on an earlier car with an engine conversion there is some modification required to the inner bay panel.

So, on the blue and white car, we were keen to explore how this could be resolved by going for throttle bodies. So some considerations were made in selecting the parts used.

As you can see in previous pictures and the ones below, I have gone for:

- A stubby and up-angled intake manifold

- Use of shorter Individual Throttle Bodies rather than DCOE based TB kits

The aim was to lift the pre Throttle Body intake above the inner bay panel whilst not compromising intake performance.

So having now positioned everything we are left with the following situation - which I see as a great result.

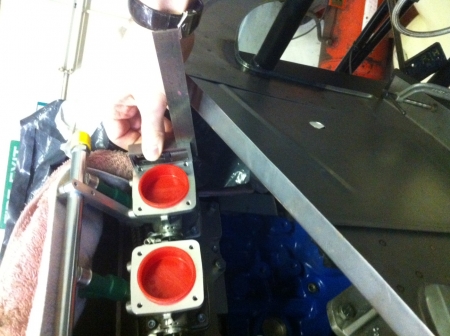

Even with the square slightly off the bottom of the TB you can see that the pesky No.1 intake will rise above the bay panel at the point off overlap. Great news - so what do we have to play with??

well... with a bit more focus - close-up

Well ~50mm (the bay panel was still only mocked up at this point).

So what to put on the end of this?!

Well there is one simple choice to make - you can either:

- Package the intake inside the engine bay

- Bring the intake out over the wing, put a scoop in the bonnet and deal with it there.

As this is a race car, I'm going to go for a longer intake and bring the trumpets out over the wing slightly and put a scoop in the new bonnet.

I'm going to use an ITG carbon shaped filter back plate:

http://www.demon-tweeks.co.uk/motorsport/universal-air-boxes/itg-carbon-fibre-trumpet-trayThey are available in 30mm depth of 60mm depth. In both packaging options outlined above, the 30mm option is the one to go for.

Now critically the trumpet length is the next thing to consider. Shorter trumpets = more peak power but trade off mid range torque slightly. Longer trumpets promote mid range torque at the price of peak top end power. It's all due to the pulse reflection in the intake tract and cam timing.

So, the Jenvey trumpets come in sizes from 19mm upto 150mm. In an engine bay packaged scenario you can go for the 19mm option however I'm going to go for 90mm brining the trumpet opening 40mm over the wing. It's worth noting at this point a standard bonnet does not come right to the edge of the inner wing and itself has a 20-30mm overlap. So this still is not really much.

Finally there is the filter depth. The ITG JC50 (the filter needed) comes in a variety of "internal heights" and it's recommended that ~18mm is left between the trumpet opening and the inner surface of the filter.

The ITG JC series filters are also available with squared edges or sausage style. So, for the engine bay packaged option, I would go for the 25mm option which will easily fit. I'll probably be going for the 100mm option - the internal metal frame supporting the filter also allows for a little shaping which should also help me as any shaping will be behind the trumpet mouth anyhow.

http://itgairfilters.com/downloads/JC50.pdfThe curved nature of the filter surface provides the additional flexibility to get the filter past the inner bay panel given the additional size vertically of the base plate.

Well, that's the idea anyhow - all parts are on order and will be mocked up next week.